AHC, the specialist closed moulding technology innovation and production house, will showcase its fibre infusion Reusable Silicone Technology ‘fiRST’, at JEC World, taking place on 25 – 27 April 2023 in Paris, France.

AHC will exhibit at the three-day event, alongside its French Partner, CMS and Nord Composites, in Hall 5, Stand T39, where members of the team will be available to discuss fiRST, the innovative closed mould technology that provides rapid production of reusable silicon membrane B tool faces.

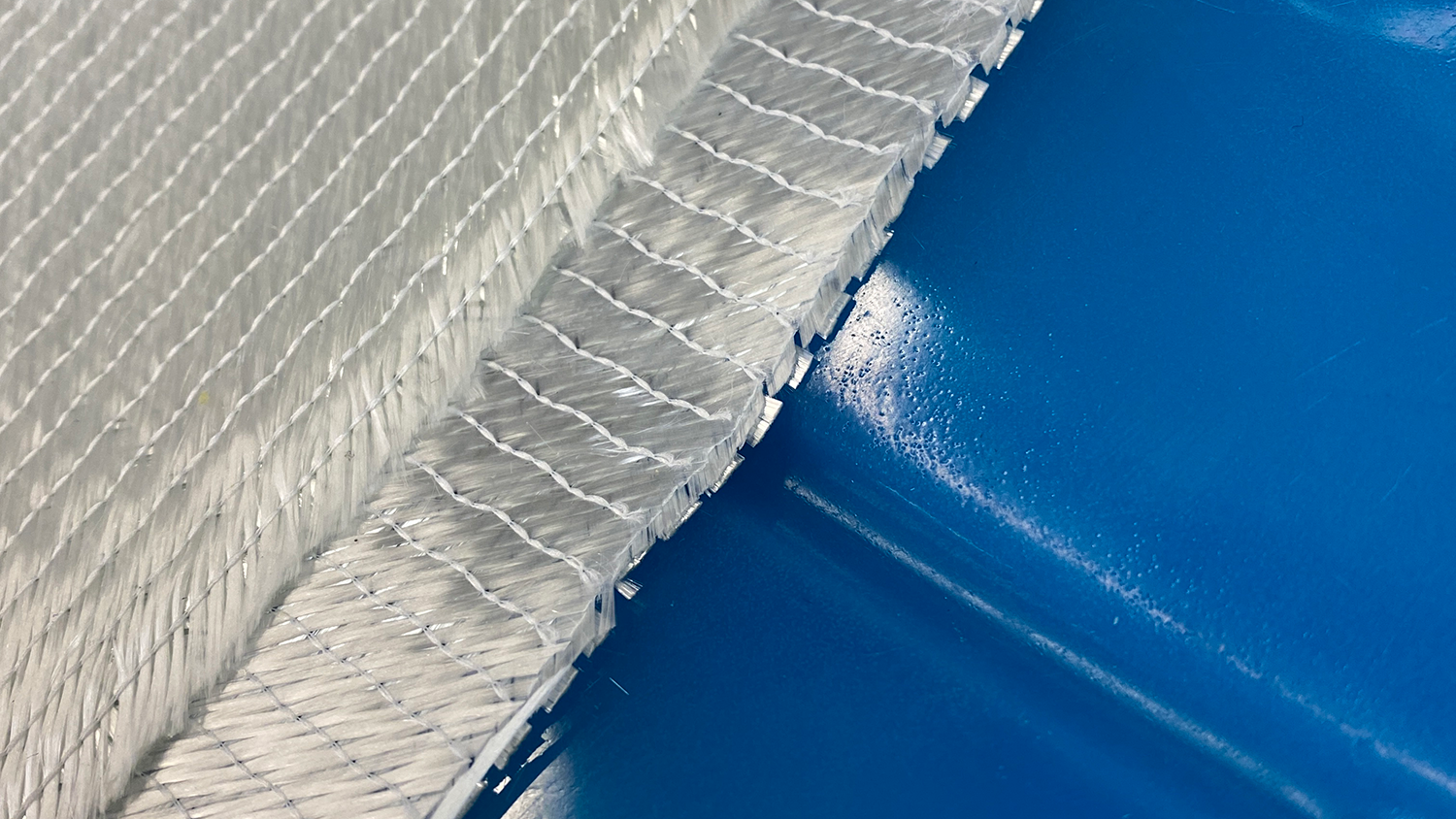

Following 12 years of research and development, AHC has led to the creation of a single use vacuum bag replacement with this technology. This step-change to eradicate consumable bagging and resin waste, provides composite moulders now with a complete reusable technology for liquid vacuum infusion as an environmentally friendly alternative to conventional consumable methods.

fiRST single reusable membranes last up to 600 moulding cycles meaning they offer a cost-effective solution after only 6 moulding cycles. In addition, the technology eliminates thousands of kilograms of plastic waste mixed with contaminated unused catalysed resin.

“It is now time to take stock and to employ newly available technology and step away from continuing to produce a legacy of waste without thought of sustainability. We are extremely proud of our achievements through our fiRST technology, especially the positive impact it will have on the environment.” said Alan Harper, Owner and Director of AHC.

AHC has received a wealth of testimonials from customers who have embraced the fiRST technology. One composite moulder, notably UK’s largest building supplier, has changed all of its RTM and LRTM work to the fiRST system due to cost and longevity advantages. Furthermore, a small two-man business has reported huge gains from fiRST explaining that it has been instrumental to its expansion including doubling its turnover during the last 12 months.

Paul Doyle, Owner of Sound Composites, states: “This is not just an alternative but in many ways a ‘game changer’ for our composite moulding industry.”

AHC will demonstrate this cost effective and far more sustainable production method as an alternative to unsound consumable bagging during the JEC show.

Website: www.alanharpercomposites.com