Frewer Engineering says it has a strong capability in Dytran simulation, with many years of additional experience in LS-Dyna, allowing the company to model high strain-rate effects such as blast, impact, naval shock, and other dynamic phenomena.

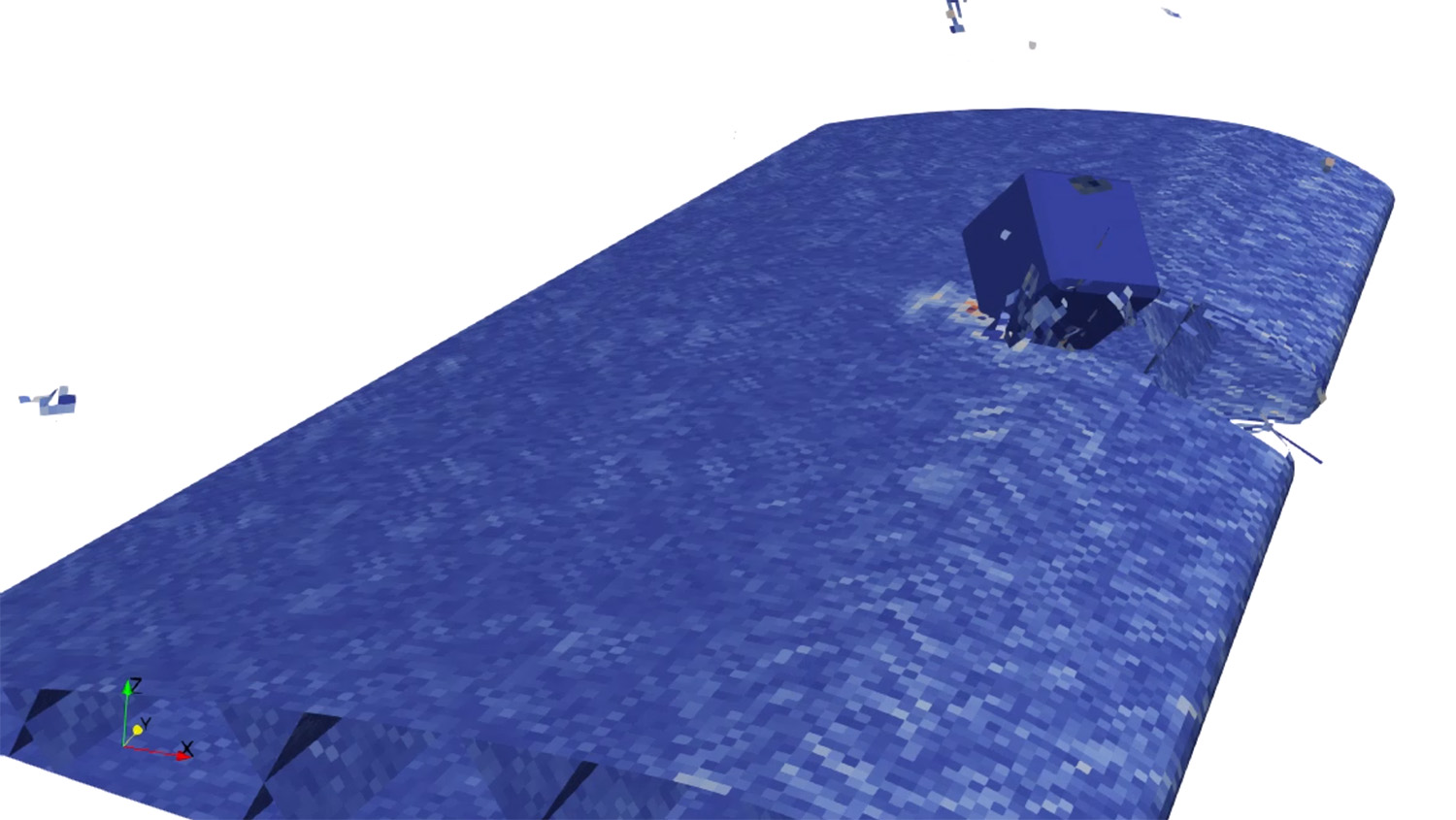

Impact between sheet metallic materials is relatively straightforward to model, including buckling, plastic collapse and ultimate-tensile failure mechanisms. Frewer is also able to model composite and rubberised layered materials in a full dynamic simulation, like the composite wing section pictured.

As with any simulation, working at the limits of what can be achieved computationally, Frewer Engineering says it will always seek real-world data to correlate against and benchmark our results, to complete the validation loop and give confidence in its simulation work.

Website: www.frewer-engineering.com