December 2022 saw a welcome milestone in the acceptance of DEECOM® ‘pressolysis’ as a recognised materials recovery method.

The revolutionary emerging technology for the circular reclamation of composites, plasticised and polymeric materials had previously seen barriers to commercialisation due to industry and academia seemingly ‘wary’ of a method so novel in its state-of-the-art that it was difficult to categorise. Many assumed that DEECOM®; a pressure-based technology which uses only steam to separate and recover organic materials from value waste streams; must be an innovation based on a known process such as pyrolysis, solvolysis or mechanical recycling. DEECOM® was in fact invented in the early 2000s to reduce the use of burning or chemicals within recycling.

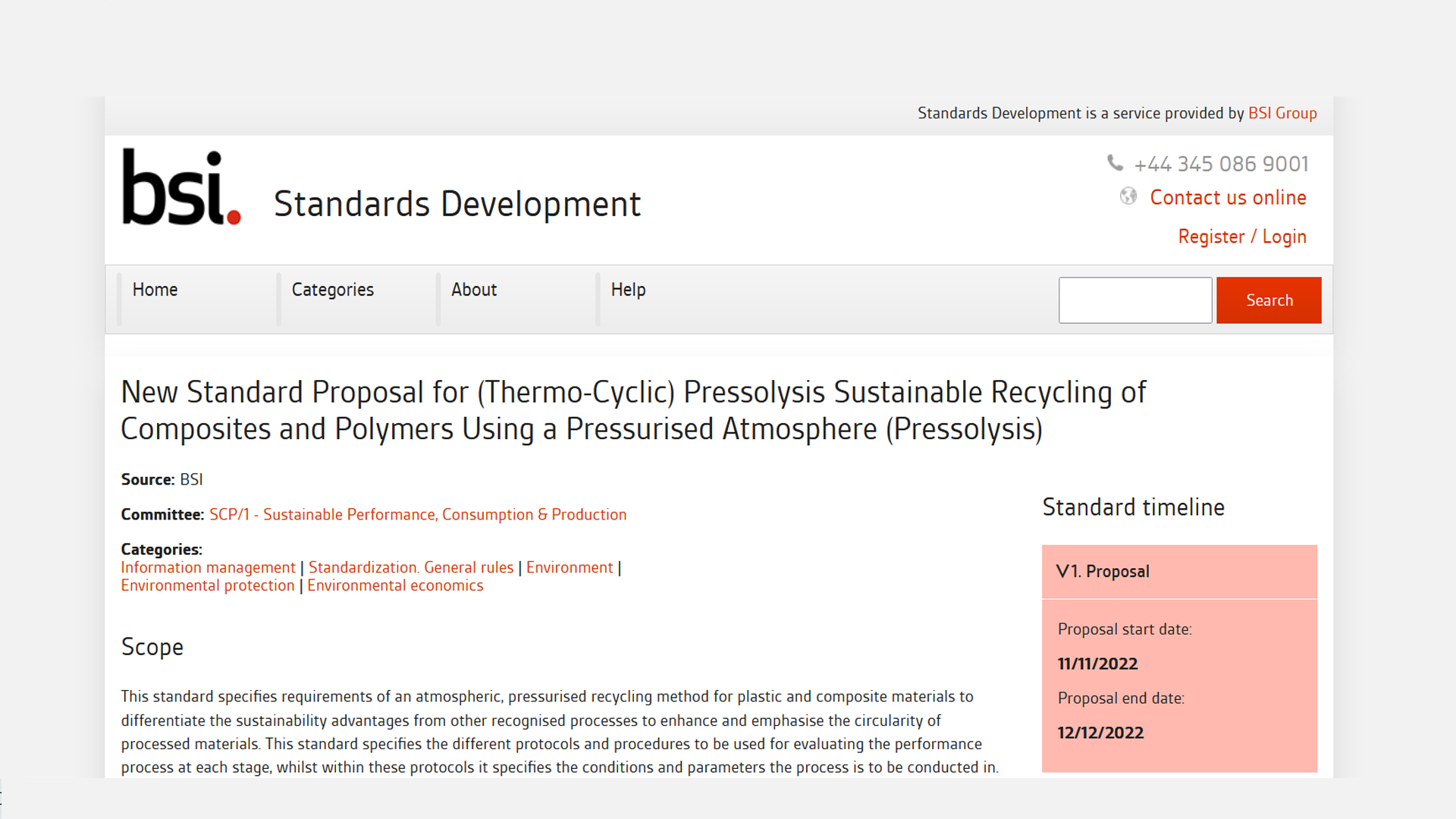

After reaching out to the team at British Standards Institute (BSI) for support in differentiating their technology, the team at B&M Longworth were tasked with writing an internal business case for the BSI to assess for suitability and relevance to the standards community. This was accepted and followed by an external business case to be published in the public domain for 4 weeks in late 2022. Longworth and several supportive partners from academia and industry promoted this nationally within the relevant sectors and markets to encourage comment, support or objection – resulting in the external case being accepted in December 2022.

“It’s crazy that an emerging technology that ticks all of the boxes can be labelled as too innovative!”

Commenting upon hearing the news, Longworth director Jen Hill said; “During the late development stages of launching DEECOM® as a materials recovery solution, we identified a challenge in that it was deemed ‘too new’, ‘too unknown’ and even at one stage were told ‘this is too novel to meet innovation funding criteria’. It’s crazy that an emerging, innovative technology that ticks all of the boxes for net zero, circularity, low carbon and British manufacturing can be labelled as too innovative!

“It was starting to cause a real barrier to commercialisation and CR&D as experts said that DEECOM® didn’t sit comfortably in any of the known methodologies. People even stated ‘if it seems too good to be true, then it probably is!’ which we heard a lot.

“By identifying the process as DEECOM® ‘pressolysis’ and with the BSI investigating our claims and accepting our business case, we’ve managed to dispel many of the concerns and unknowns and to explain the science behind DEECOM®. This is a huge step forwards in the emergence of a technology which we truly believe can bring a global step change to materials circularity, displacing virgin raw materials.”

Next steps for DEECOM® pressolysis?

A drafting panel of technologists, engineers, academics, industry representatives and materials specialists, including the original inventors and staff from Composites UK, has now been compiled and approved for the standard writing to progress in Q1 of 2023.

For a snapshot of the proposed British Standard for pressolysis reclamation, visit BSI.

Website: www.deecomlite.com