Frewer Engineering makes use of LS-Dyna, Dytran and various custom codes to develop high strain-rate dynamic models, capable of simulating metallics, composites and a range of other novel and non-standard material models. Bespoke material models may include bricks, mortar, biological tissues including bone, pre-tensioned cables, and inflated membranes in tension.

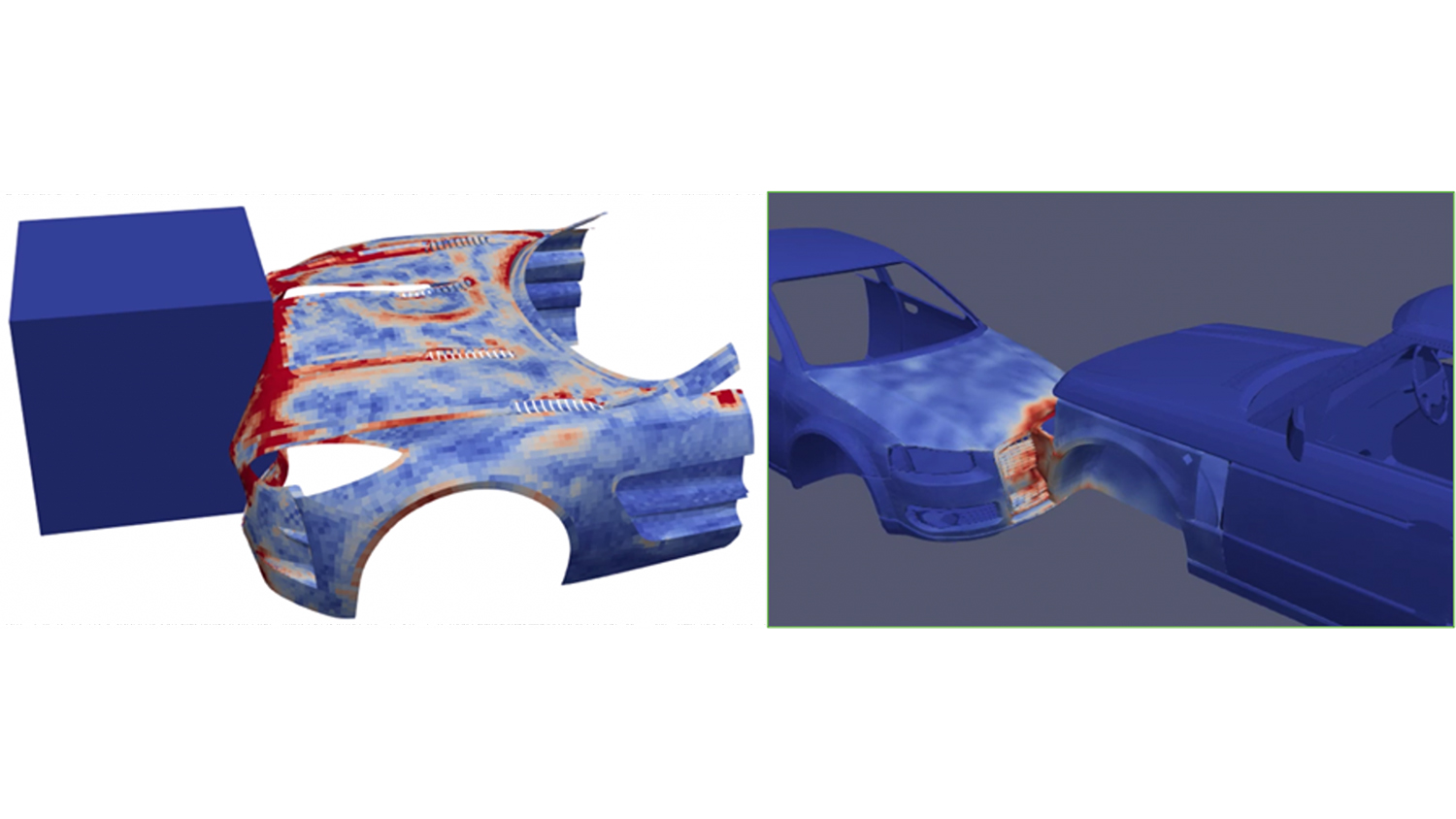

Simulations can extend from automotive crash simulations (pictured above) to computational drop tests, bird-strike, blade-off and disc-burst containment checks for aerospace propulsion systems, as well as firing simulations for launch systems.

Frewer Engineering is proud to provide this service to our customers, helping simulate high strain rate events, such as impacts or explosions, in both metallics and composites, as it helps accurately predict material behaviour under extreme conditions, ensuring reliable performance assessments and cost effective design optimisations.