Glass Reinforced Plastic (GRP) is fast becoming the defining material of Britain’s next infrastructure revolution. Once viewed as a specialist alternative to steel or timber, GRP is now leading the transformation of sustainable construction across the United Kingdom and Europe. From transport networks and renewable energy facilities to marine defences and manufacturing plants, the material’s strength, light weight, and resistance to corrosion are reshaping the way Britain builds.

Recent analysis places the UK GRP pultruded profile and grating market at approximately £90 million in 2025, with forecasts predicting it will exceed £130 million by 2030. This represents sustained annual growth of between seven and nine percent, driven by demand for more sustainable, long-life materials across the construction, energy, and infrastructure sectors.

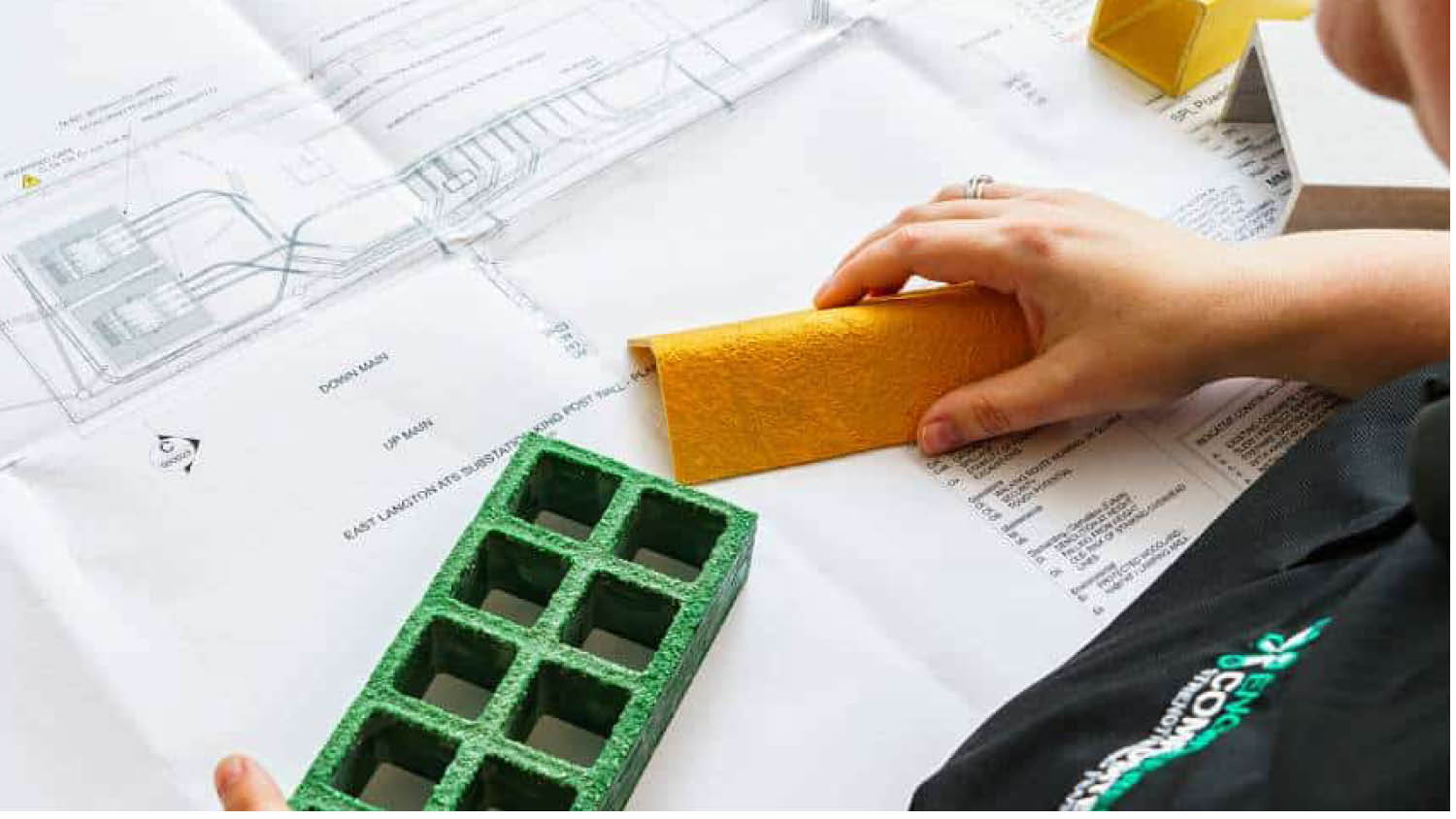

“GRP is no longer a niche product, it’s central to how we deliver safe, efficient, and sustainable infrastructure,” said Gavin Williams, Director of Engineered Composites. “We’re seeing unprecedented growth from contractors and designers who recognise that the materials chosen today must deliver both performance and environmental responsibility for decades to come.”

The Drivers Behind the GRP Boom

Three key forces are propelling this growth: sustainability, resilience, and innovation. Every major UK sector is under pressure to reduce embodied carbon, and GRP offers an immediate advantage. It is around 70% lighter than steel, dramatically cutting transport emissions and installation energy. It also requires no painting or galvanising, making it virtually maintenance-free throughout its 50+ year service life.

In terms of performance, GRP thrives where traditional materials fail. Its corrosion resistance and non-conductive properties make it ideal for use in chemical processing plants, water treatment facilities, rail infrastructure, and coastal installations. This long-term resilience translates into reduced lifecycle costs and a lower carbon footprint for asset owners.

Regional Growth Across the UK

The North West has emerged as an industrial powerhouse for GRP adoption, supported by chemical, utilities, and manufacturing projects in Cheshire, Lancashire, and Greater Manchester. The South East and London continue to lead in high-performance construction, with major developments such as Crossrail and Thames Tideway showcasing GRP’s role in safety systems, access routes, and cable management. In Scotland, renewable energy and coastal infrastructure are driving record demand for GRP platforms, fencing, and anti-slip walkways, while the Midlands and Wales are investing heavily in utilities, flood defences, and manufacturing upgrades that favour durable, corrosion-proof materials.

Export Opportunities and European Expansion

As Britain’s domestic market matures, growth opportunities are expanding across Europe. With the EU’s Green Deal and national carbon strategies accelerating the adoption of sustainable composites, demand for GRP is increasing in Germany, the Netherlands, Denmark, and Spain. Engineered Composites, with its ISO 9001 certification and compliance with BS EN 13706 and BS 476 Class 2 fire ratings, is well-positioned to support contractors across the continent. Export growth is expected in renewable energy infrastructure, hydrogen facilities, and data centre construction—sectors where non-conductive, corrosion-resistant materials are critical.

Britain’s Leadership in Composites

For nearly forty years, Engineered Composites has been at the forefront of the GRP revolution, supplying pultruded profiles, gratings, handrails, and fencing systems that meet the most demanding industrial standards. The company continues to invest in innovation, sustainability, and technical expertise to ensure British composites remain competitive in a growing European market.

“The UK has the experience, the talent, and the manufacturing base to lead Europe’s shift toward advanced composites,” Gavin Williams added. “As more industries prioritise long-term sustainability, GRP will underpin a new generation of low-carbon, high-performance infrastructure.”