Norco was approached to develop a long-term replacement for the non-metallic anti-climb barrier brackets installed on a fibreglass perimeter fence surrounding an RF-sensitive facility. The original brackets, believed to be hand-laminated GRP, had deteriorated after years of exposure. With no drawings, moulds, or supply source available, maintenance had become increasingly difficult.

Norco engineered a 3D-printed, non-conductive, UV-resistant and dimensionally consistent replacement part, manufactured in volume using a daylight-cured stereolithography (MSLA) process.

A total of 180 units were produced to support full refurbishment and spares for ongoing maintenance.

Project Requirements

The fence system operates in an environment where metal components cannot be used due to the risk of radio frequency interference. The new solution therefore needed to be:

• Non-metallic and RF-transparent

• Compatible with existing fence post geometry

• Durable in outdoor environments (UV, moisture, weathering)

• Structurally reliable for supporting non-metallic rotary barbs

• Repeatable and dimensionally consistent across all units

• Lightweight to prevent unnecessary load on the fence system

Design & Engineering Approach

With only physical samples of the failing component available, Norco’s engineering team:

• 3D scanned the legacy part to capture geometry despite inconsistencies caused by manual layup.

• Reverse-engineered a new CAD model optimised for additive manufacturing.

• Introduced new reinforcing features to prevent stress failures previously seen in service.

• Designed the bracket to accept plastic fasteners only, meeting the requirement for a zero-metal assembly.

• Improved fixing strength by incorporating cross-fixing points at 90° to the original orientation, adding structural integrity in two load directions.

Material Selection

The component was printed using a UV-cured thermoset resin developed by Photocentric with BASF. This material offered the required:

• Low moisture absorption

• High UV stability

• Impact resistance & elongation properties

• Characteristics aligned with nylon / polypropylene-type mechanical behaviour, while benefitting from thermoset chemical stability.

A NATO-grade external coating was applied to enhance long-term outdoor performance.

Additive Manufacturing Process

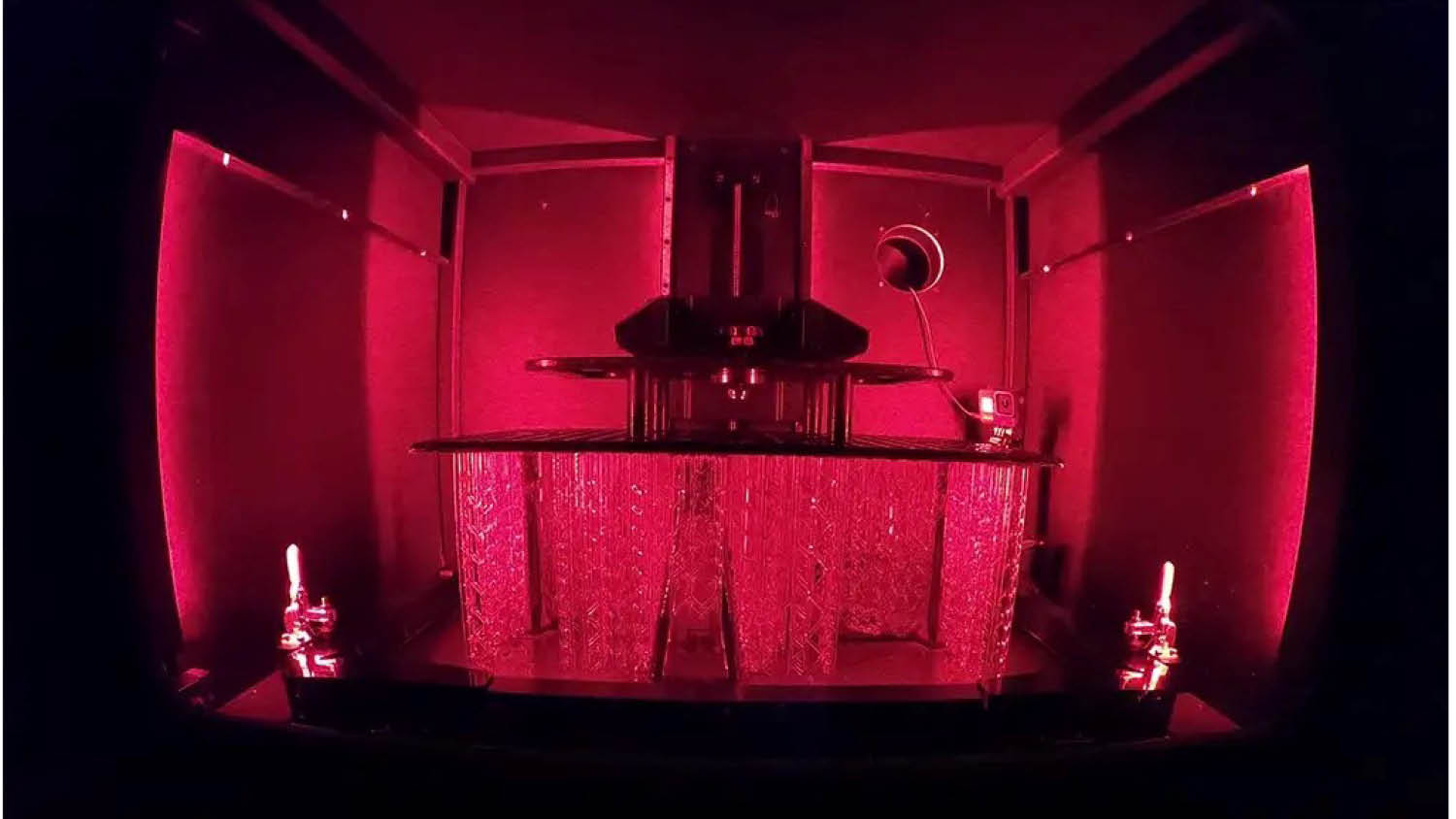

Technology used: Masked Stereolithography (MSLA) — a process where each layer of resin is exposed in a single flash, allowing multiple parts to be printed simultaneously without increasing print time.

Engineering challenges addressed:

| Challenge | Solution |

| Dense wall sections near wire connection points risked localised print sagging | Adjusted print orientation and exposure strategy |

| Variation in legacy parts required tolerance strategy | Parametric CAD model refined through iterative prototyping |

| Added reinforcement risked weight & material increase | Design optimisation to avoid unnecessary mass and cost |

Testing & Validation

Although the part is not subjected to high loads in operation, Norco carried out:

• Physical impact and drop testing

• Coating adhesion validation using scratch and pull-off tests

Pull-off testing showed performance meeting or exceeding thresholds used in marine and automotive sectors, providing confidence in coating durability for long-term external use.

Outcome

Norco delivered 180 production components, supporting refurbishment of the full fence perimeter and providing spares for future maintenance.

Key results:

• Eliminated supply chain dependency on a legacy, hand-laminated part

• Delivered a repeatable, quality-controlled additive component

• Enhanced installation performance through structural and fixing improvements

• Provided a non-conductive, RF-compatible solution suitable for sensitive environments

Summary

This project demonstrates how additive manufacturing and composite expertise can successfully solve obsolescence challenges where:

• Original manufacturing data is unavailable

• RF transparency and non-metallic construction are essential

• Long-term weather performance is critical

By combining 3D scanning, design for additive manufacture, advanced resin chemistry, and validated coating systems, Norco ensured a robust replacement part for a critical infrastructure application.