Dura Composites and Anderton Concrete are teaming to help Energy and Infrastructure customers access the best in pre-cast concrete troughs and GRP composite trench covers from a single supply chain source partner.

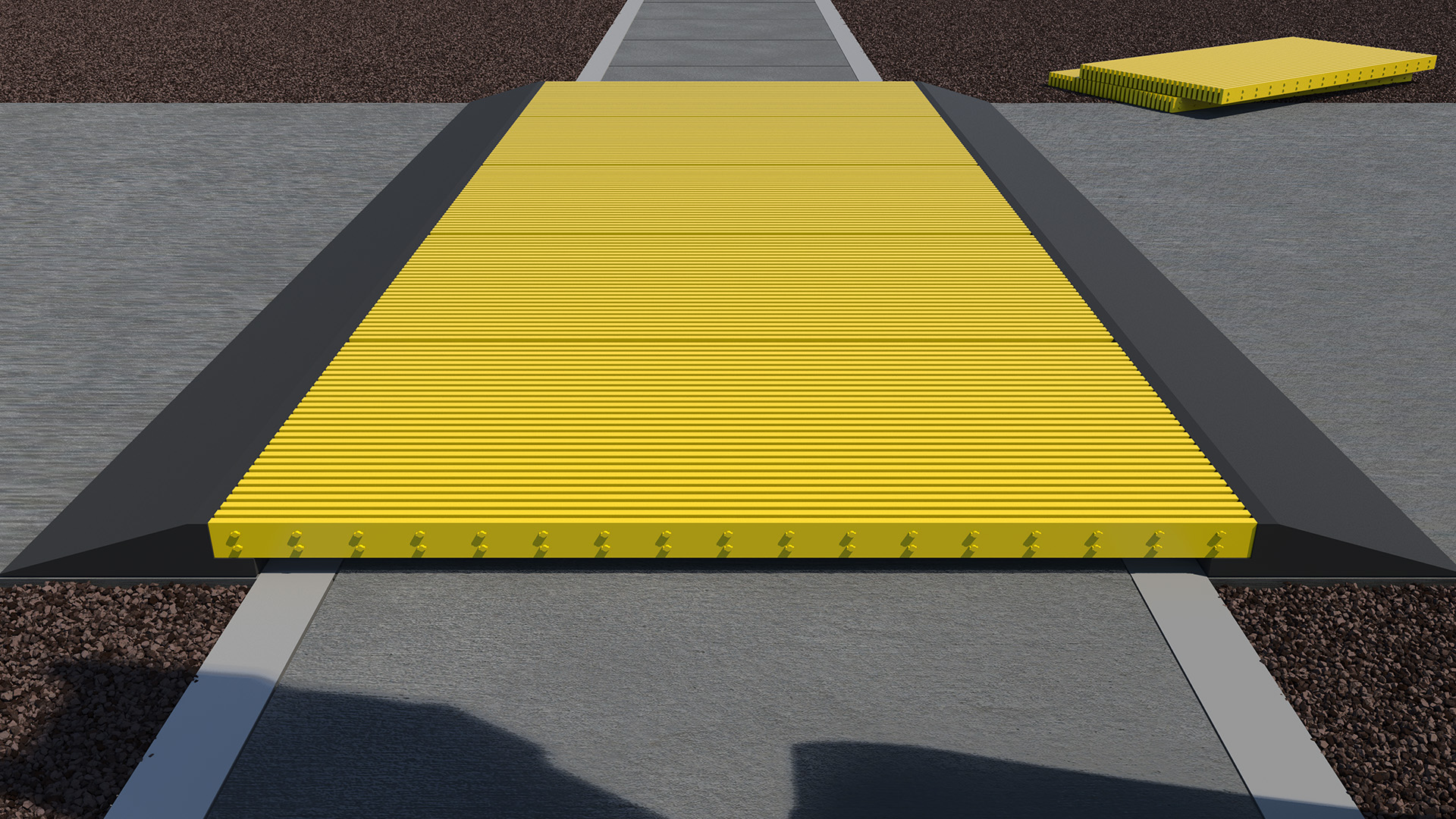

Anderton Concrete, well known for manufacturing market-leading rail and structural precast concrete products, is now enhancing its offering of pre-cast reinforced concrete troughs to include solutions specially designed for the Power and Energy infrastructure sector. Through its partnership with Dura Composites, it will now offer a full solution of lightweight and non-conductive GRP trough lids, including moulded open mesh Dura Grating for pedestrian loadings and solid pultruded Dura Slab lids for vehicular loadings.

With over a decade of experience in supplying specialist GRP composites to the energy sector, Dura Composites have seen a marked increase in customers requiring a combined concrete trough and GRP lid system. GRP lids allow for easy manual handling, simple installation on site, and have a gritted anti-slip surface that requires minimal maintenance. Dura Composites’ GRP lids can also be fitted with an ingenious mechanical lifting system which eliminates the need for heavy plant machinery whilst ensuring accessible inspection at all times.

Crucially, Dura Composites GRP trench covers have undergone extensive testing using UKAS accredited laboratories to comply with BS EN 124 and FACTA requirements, as well as a wealth of supplementary in-house testing, using our fully calibrated test facility that can replicate project conditions and provides clients with the ultimate peace of mind.

The partnership will provide UK Energy sector customers with locally available stock of concrete troughs and GRP lids alongside and high levels of local technical engineering support. To help raise standards within the industry, Dura and Anderton has consulted with a range of energy sector specialists to ensure the latest designs meet current requirements, whilst also incorporating several new innovative features.

The two companies have previously worked together on several successful projects in the past including one mile of concrete troughs with GRP lids installed as part of the Crossrail project.

The collaboration will also help Dura Composites deliver on its ambition to make the use of composite products mainstream and is the latest in a series of major developments for the company, which recently won its second Queen’s Award for Enterprise.

Commenting on the partnership, Joe Hunt, Industrial Sales Manager at Dura Composites said; “Dura Composites’ goal of unlocking the power of composites for the energy sector builds on our core mission of combining innovative products with unique manufacturing methods to deliver the safest, most cost-effective and durable solutions on the market. This new partnership comes at an ideal time for Dura Composites as the business goes through a period of significant growth and expansion. Our partnership with Anderton Concrete will enable both partners to apply our unique knowledge and skillsets to supply combined trough and lid solutions that solve the core challenges the industry has been experiencing for years. Anderton Concrete’s existing customer base will also be able to benefit from Dura Composites’ high UK stock holding, technical support and structural design services to deliver tangible added value.”

Tim Fields, Technical and Development Manager of Anderton Concrete continued; “Anderton Concrete are committed to ensuring complete customer satisfaction by continually improving our performance in the development of the products, quality, techniques and services we offer. By partnering with Dura Composites on the supply of GRP trench covers for our new energy trough range our customers will now benefit from unrivalled load and span safety and choice.”

The Dura Composites and Anderton Concrete partnership follows Dura Composites’ successful introduction of its d2 product range. Developed from 25 years’ experience, d2 products feature unique designs, new material technology or manufacturing methods and deliver class-leading performance. An example of the runaway success of the range is our GRP floor grating known as d2 Dura Grating. It offers outstanding safety, performance, and durability versus previous generation products found elsewhere in the energy sector and has a Class B fire rating in accordance with BS EN 13501-1 as standard. It retains 95% of its anti-slip properties after and incredible 1 million footfalls, so customer can have greater peace of mind in industrial environments.

Website: www.duracomposites.com