With Tebis 4.1 Version, there are a number of ways for optimising and automating your CAM pro-gramming. One of the ways is the process template for CAD/CAM automation. Tebis software can export any kind of CNC program process and is able to reimport this process, change some basic pa-rameters to replicate the original process but on a completely new component.

Joe Zhou, Managing Director at Tebis UK explains: “With ever rising labour costs and a getting-worse labour shortage, Artificial Intelligence and automation are getting more important day by day. Manufacturing best practice experience and data are very valuable, and CADCAM systems should support the accumulation and share of valuable manufacturing process and data.

Traditionally, CAM programming is mostly about calculating toolpath, however, for improved productivity, quality and safety, a lot emphasis should be on CNC machining process and cutting condition optimisation. For this reason, Artificial Intelligence and Automation should play a very important role for future CAD/CAM technology development”.

Tebis software is able to pre-select the surfaces and the starting stock necessary for manufacture by geometry layers, colours and attributes together with variable statements within the programming operations. Tebis also supports user-defined variables to control CNC machining process.

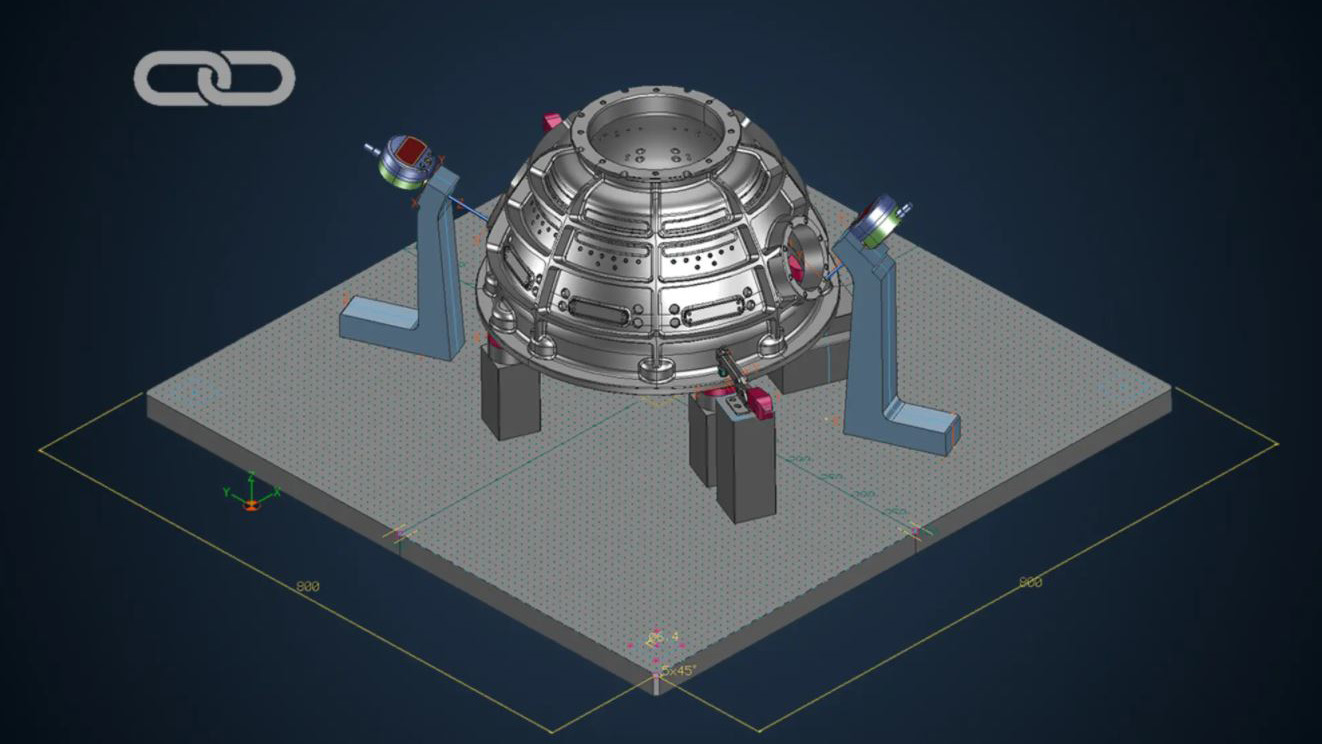

For example, with Tebis CAM automation, CAM programming of this vacuum fixture is just an exercise of organisation of data. If the data is on the correct layers then Tebis will machine the component automatically and correctly. This means an inexperienced engineer can produce work that is of the same standard and consistency of your experienced CAM programmers, leaving your more experi-enced programmers to get on with higher complexity and higher value work such as optimising CNC manufacturing processes.

Tebis advanced parameter selections in Tebis Templates are able to incorporate the use of feature recognition and the use of NCSets within a machining template making the template package extreme-ly powerful and very flexible. Geometry feature dimensions and attributes can also be used to auto-matically choose cutting tools, machining parameters and machining processes.

Tebis template supports automatic tool axis orientation, automatically generating very complex 3+2 machining NC programs. Once the CAD work is done Tebis template takes care of all the programming, leaving the programmer to continue on more pressing work. This template method along with Tebis virtual machine technology means that the user can program, for example, the full clay model “hands off” then send the setting data to the machinist who sets the model on the machine and then runs the program with little supervision.

Major innovations

Faster preparation for manufacturing: Highly automated, flexible preparation for CAM programming with parametric CAD templates.

Every imported data set has to go through a CAD process in preparation for CAM programming. This usually takes many individual work steps: Bores for clamping systems must be placed, tilt axis systems defined, fill surfaces designed, blanks created, connection points for setups generated, clamping de-vices positioned and retract planes defined. With the latest realse of Tebis 4.1, these many individual steps can be automated using Tebis parametric CAD templates. These templates can be extended as needed and modified to meet customer-specific requirements. Users can remain flexible: changes like the selection of a different clamping system can now be controlled directly and conveniently with the user parameters in the object tree.