Hypetex and Philip Morris International (PMI), owners of the heated tobacco devices brand IQOS, have recently collaborated on a development program to create coloured carbon composite covers for IQOS tobacco heating devices.

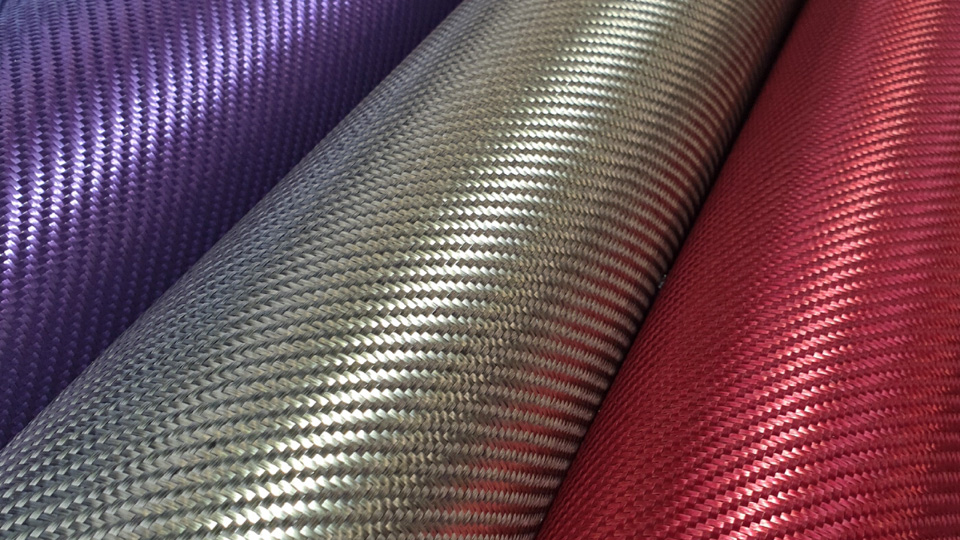

Tobacco heating devices offer a smoke-free alternative that provide a better choice for those that would otherwise continue to smoke. PMI approached Hypetex with the objective to identify a viable composite material solution to create the IQOS accessories in coloured visual carbon, as well as defining an easily scalable production process and manufacturing supply chain using Hypetex’s unique in-mould, coloured composite technology.

When potential customers such as PMI come to Hypetex to discuss a unique colored carbon fiber finish, the Hypetex team provide the pathway and expertise to develop a much wider scope, particularly if the product design is still at the concept stage. For the IQOS development project, Hypetex coordinated all aspects of the design, engineering, materials, and technical direction from the initial concept through to the final solution selected for production.

Thermoset and thermoplastic materials were considered for the IQOS cosmetic covers, but early-stage trials showed improved results with thermoplastics. As a result, Hypetex coloured 3K twill weave carbon fibre fabrics with polycarbonate (PC) organo sheets were chosen for the final parts, with Hypetex turning to Formaplex for manufacturing capacity and technical support as the compression moulding, machining and then overmoulding processes were finalized.

The key challenge for the IQOS cover manufacturing team was to keep processing time to a minimum. Multicavity tooling and machine jigs met the compression moulding and CNC machining requirements before the Hypetex carbon covers were returned to the moulding machine for overmoulding with transparent PC materials. A final two coat protective lacquer was applied, with 50 parts per process batch keeping cycle time to a minimum.

The final part of the manufacturing operation, and a key requirement for the IQOS brand was to prove out the process for the application of IQOS logos for the new carbon cover parts. Promising initial results were quickly optimized, with a jig holding multiple parts and a rapid laser etching process satisfying all the PMI branding specifications.

With all proof-of-concept work completed, a batch of 300 prototype parts was manufactured. Total per unit cycle time was only five minutes per unit, with the initial batch run identifying further cycle time reduction opportunities for a fully optimized production process.

Marc Cohen, CEO at Hypetex, said, “The IQOS components were a challenging project for us, bringing together several tooling concepts and coordinating manufacturing processes for the final tightly tolerance multi-material parts, all achieved within the shortest possible cycle time. For these types of consumer products, Hypetex provides customers with an end-to-end solution enabling coloured carbon composite finishes as part of a fully integrated manufacturing processes.”

Website: www.hypetex.com