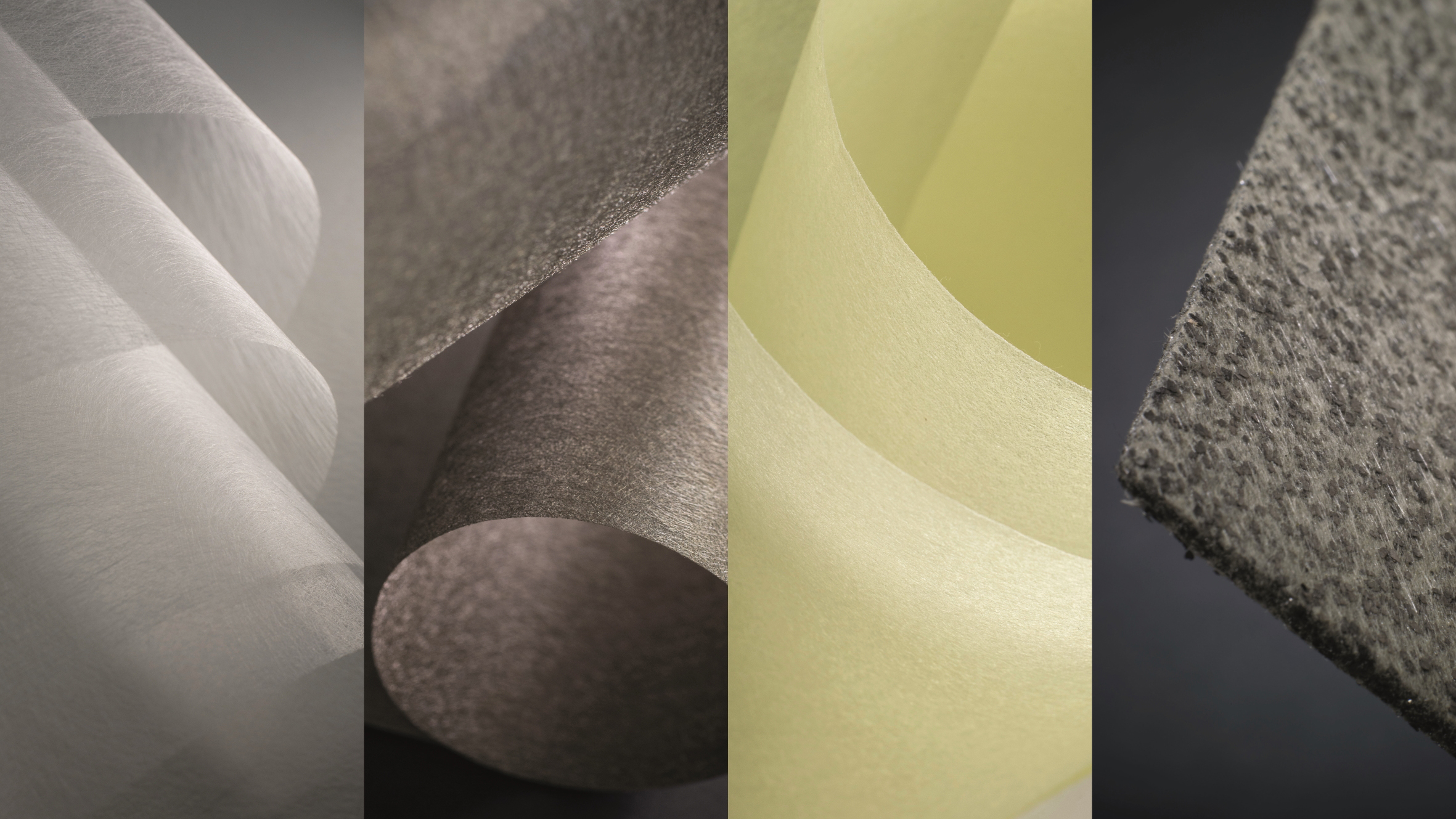

CAMX will be opening its doors on 17th October and TFP Inc. will be exhibiting their advanced nonwovens on booth J11 at the event. On display will be materials from the Optiveil®, Optimat® and Tecnofire® ranges, all specifically designed to provide solutions for key composite challenges.

TFP’s Optiveil® and Optimat® materials are multi-functional; designed to overcome a number of challenges in composites using a single material. Their highly porous structure enables enhanced resin uptake and transportation, aiding fabrication and lowering resin usage. While the consistent, even fibre distribution of the veil enables a high quality, resin rich surface finish, reducing print though and processing. The veils are lightweight and available in a wide range of fibre types to confer additional functionality in addition to these fabrication benefits. Typical examples are:

- Metal coated carbon fibres which impart EMI shielding for battery and electronics enclosures, as well as conductivity for resistive heating applications.

- Aramid fibres to improve surface abrasion resistance for friction substrates in automotive, sporting goods and roll covers.

- Glass and carbon fibres can provide a corrosion resistant surface for industrial applications as well as managing static dissipation.

- Dielectric fibre veils can be incorporated as an electrically isolating layer to prevent the electrochemical reaction that causes galvanic corrosion.

As well as surfacing applications TFP’s veils can also increase the longevity of the composite; interleaving thermoplastic veils between reinforcement layers can improve the mode-I and mode-II interlaminar fracture toughness of the structure by up to 400%!

The Tecnofire® range of lightweight intumescent fire protection materials will also be on display on the stand at CAMX. These materials enable composites to pass stringent reaction to fire and fire resistance test standards and have been used extensively in applications such as infrastructure, construction, mass transport and aerospace. It provides built in composite fire protection without compromising the integrity of the structure and has been used effectively to pass key reaction to fire standards including ASTM E662, E162 and the EN45545-2 rail sector standard. Tecnofire® is incorporated directly into a composite structure using traditional fabrication methods, protecting the structure from fire while reducing smoke and heat release. It can also be combined with FR resins and integrates well into FR laminate composite assemblies.

In addition to the Optiveil, Optimat and Tecnofire ranges, TFP specializes in developing or adapting materials to meet customer specific performance, processing and aesthetic requirements. This is enabled by extensive product development capabilities, ranging from proof of concept lab work to trials, full scale manufacture and converting via lamination and nanocoating.

Talk to the team on booth J11 at CAMX to find out more about TFP’s capability and explore how their innovative materials can help deliver a solution to your technical challenge.

Website: www.tfpglobal.com