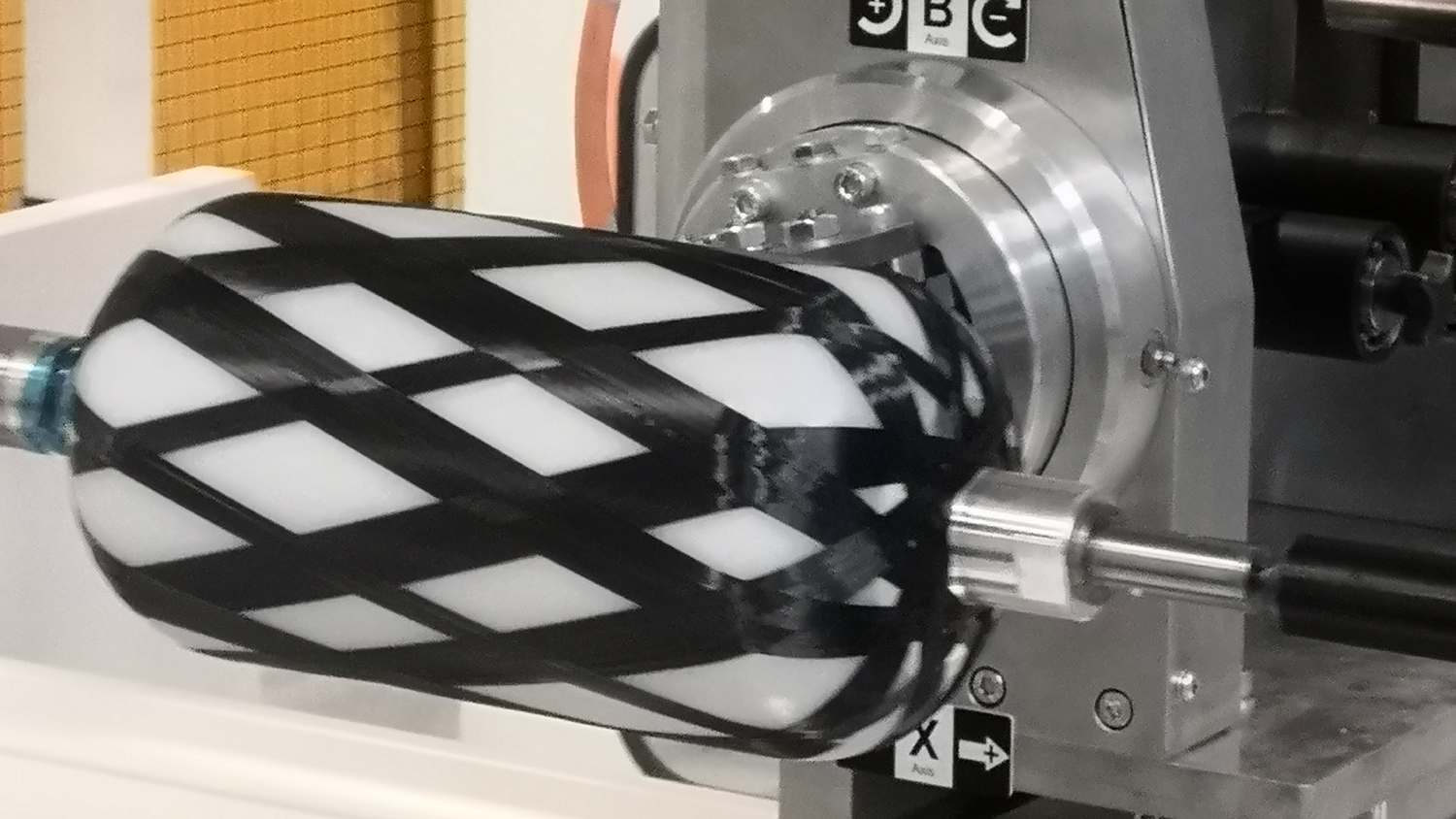

Cygnet Texkimp has delivered a four-axis filament winding machine to the National Composites Centre (NCC) where it will form part of a new state-of-the-art manufacturing and test facility for hydrogen transportation and storage.

The multi-functional filament winding technology has been developed by Cygnet Texkimp to provide the NCC and its partners with the capability to wind all types of filament from towpregs to dry fibre and glass fibre, and all combinations of fibres and resins including high viscosity and fast cure resins.

“We’re extremely proud to see our filament winding technology forming part of the NCC’s world-leading Hydrogen Programme,” says Cygnet Texkimp CEO Luke Vardy.

“The work of the NCC and its partners stands at the forefront of an exciting new era of hydrogen tank design and development and plays an important role in anchoring this area of manufacture in the UK.

“The technology we’ve delivered offers high levels of flexibility and capability to meet the requirements of many different filament winding applications and support the NCC’s pioneering development work.”

Marcus Walls-Bruck, Head of Hydrogen at the National Composites Centre said, “Acquisition of the Filament Winding machine builds on our investment in capability development for hydrogen, with this machine predominantly focused at pressure vessels.

“It will help the UK create supply chains to achieve its net-zero ambitions. A key technology that underpins our state-of-the-art design, test and manufacturing facility for hydrogen, it will be used to create pressure vessels for a number of applications, with this capability supporting industry in developing business cases and products to enter this growing market.”

The filament winder is designed to wind four tows simultaneously. Each tow has its own tension control unit and dancer arm which regulates feeding and winding tension to enable faster and more accurate winding.

A customised software package, developed by Cygnet Texkimp’s in-house team, also allows the NCC to record data including winding tension and speed, resin temperature and air pressure within the mandrel.

The filament winder is served by two four-position creels, which are designed to feed different types of fibre into the process. A towpreg creel unwinds and guides towpreg material into the winder and is an essential part of a novel solution designed to completely isolate the tension required at the bobbin from the tension desired during the winding phase, in order to ensure that the fibre is fed optimally at all times. A second, dry fibre creel feeds fibres into the process at low tension and high accuracy and is enclosed to prevent the release of airborne debris into the environment.

The machine also features two types of in-line spreading and coating capability which can be quickly and easily deployed for dry-wind applications: a temperature-controlled wet-out system with adjustable spreader bars to spread individual fibre tows for consistent resin impregnation, and a coating drum and blade to control the volume of resin applied to the fibre. Both of these methodologies will be investigated by the NCC for their suitability in winding applications across a range of applications.

Website: www.cygnet-texkimp.com