• High-precision metering pumps improve fibre-to-resin control, boost efficiency and reduce waste in composites manufacture

• Metering systems handle the most challenging resins and polymers

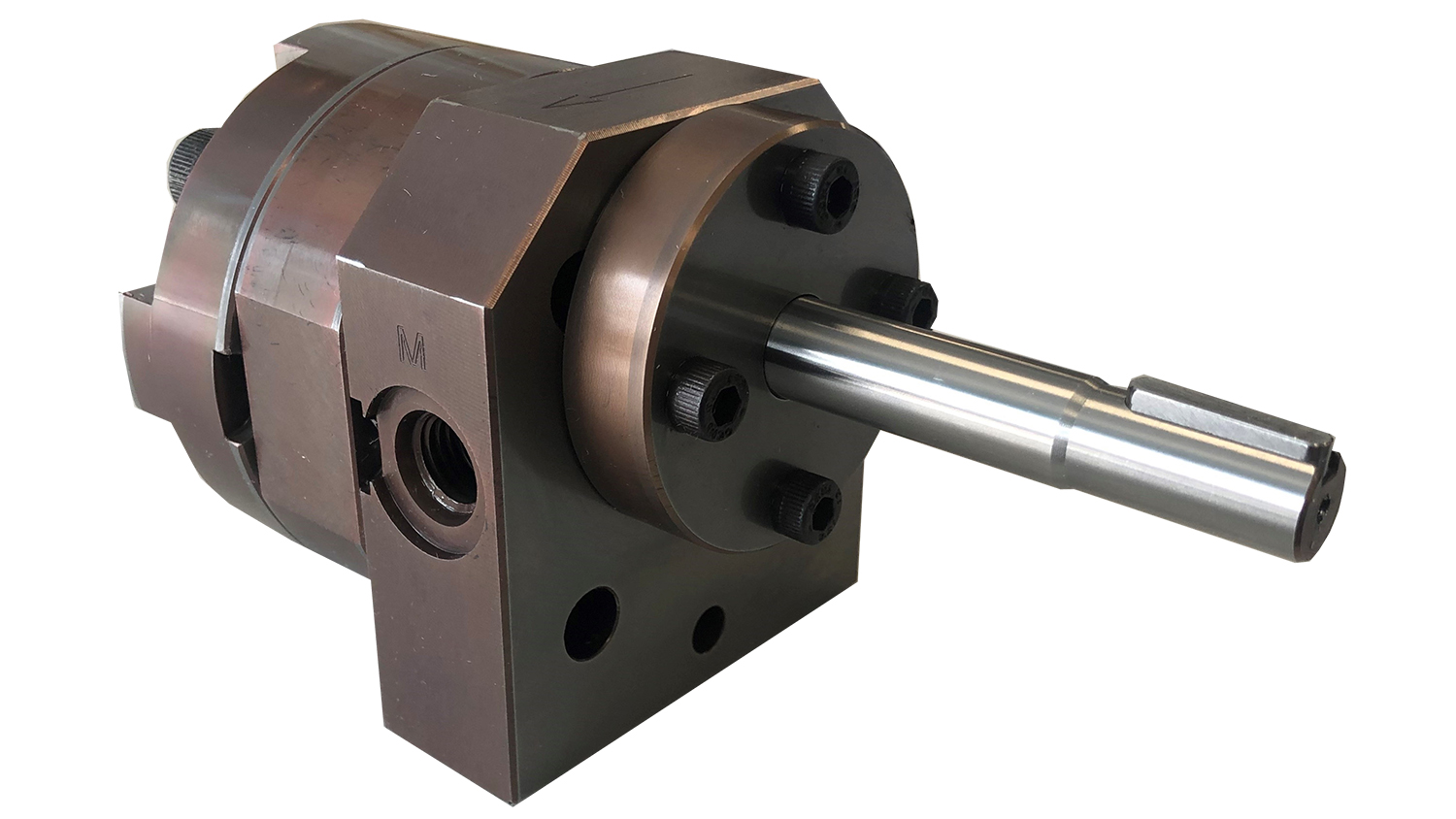

High-precision gear pump manufacturer Slack & Parr (Derby, UK; Hall 6, S62 & T62) will present its resin metering technologies and highlight how they are helping manufacturers develop lighter, stronger composite materials and parts, accurately and at rate.

Exhibiting on the Composites UK stand, Slack & Parr will showcase the benefits of its metering solutions, which are designed to improve accuracy in fluid mixing, flow and dosing, giving manufactures greater control in the downstream processing and application of resins and polymers.

Visitors will discover how the company’s bespoke gear pumps can be customised to handle the most challenging materials, from very low viscosity polymers processed under high pressure to fast-cure resins that require in-line mixing and high-speed application.

Slack & Parr is the world’s leading supplier of gear metering pumps for the production of PAN precursor used to manufacture carbon fibre. Its technologies are used in many composites manufacturing processes including coating, prepreg, filament winding and spraying, as well as in extruder-based processes most commonly used in the manufacture of thermoplastic composites.

“Our precision metering technologies are designed to overcome challenges associated with the downstream processing of resins and polymers to improve accuracy and efficiency at every stage,” explains Neil Anderton, Industrial Director at Slack & Parr.

“We pride ourselves on delivering the most accurate, robust, and reliable gear pumps in the world, tested and developed over many decades. This unparalleled engineering expertise means that we are able to customise each pump to match the exact requirements of the application, which is proving crucial in the rapidly evolving resin technology and materials science industries.

“Our pumps promote successful outcomes for composites-intensive products where fibre-to-resin ratio is an important measure of weight, strength, and performance in the finished part. We help manufacturers achieve desired ratios in a way that is consistent and repeatable while also increasing speed of production and reducing waste.

“Last year’s JEC presented us with some excellent opportunities, and we are looking forward to repeating that success in Paris this year.”

Slack & Parr’s metering pumps are built around hardened steel involute gears which are machined to precise tolerances of one or two microns. This results in extremely small, controlled clearances – measuring significantly less than a human hair – between the gear and mating components, ensuring almost no internal slip even at high pressures. This level of precision means the pump is able to control or meter the flow with extreme accuracy and repeatability.