For over 40 years, Tebis CAD/CAM and MES offers advanced solutions for model, pattern, die and mould making as well as mechanical component manufacturing. Tebis also helps customers to optimise CNC machining processes and to automate CAM work with Intelligent Manufacturing technologies.

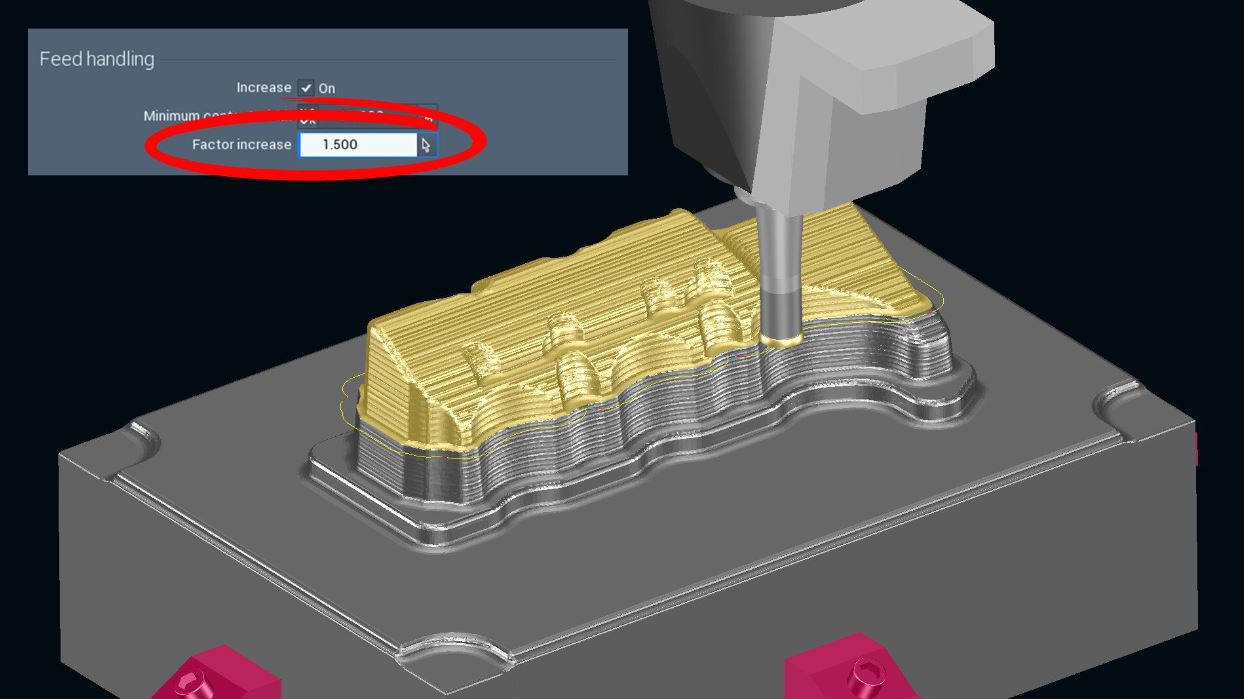

With the latest Tebis release, there are many new features and extensions offering even more automation for design, data preparation, CAM programming and CNC machining process optimisation. One of the main addition of features is roughing feedrate optimisation. The new feature will raise the feedrates where the material removal rates are low. This is in addition to existing features to reduce feedrates where there are fullwidth cuts or round corner cuts.

Paul Scally, Operations Manager from Tebis UK, explains: “When performing roughing cycles on components, the actual cutting time on the machine can be quite intensive, especially if the feedrates are not correctly set, requiring the presence of a machinist to manually adjust as the part is being machined for changes in direction, plunging, ramping etc and also in relation to the amount of contact cutter has with stock material.

With Tebis CAD/CAM Software these parameters can be set in our 5 dimensional tool machining parameter library which contains 12 cutting parameters with the addition of cooling setting.

These parameters enable Tebis software to control the cutting feedrates for standardised and optimised machining times also including recommended stepover, depth of cut and maximum contact width of the cutter values.

With these parameters, Tebis CAD/CAM software is able to apply these changes feedrates in the post processor output and even reduce the feedrate for areas where the full width of the cutter are engaged or adapt the toolpath the to avoid a full width cut as the toolpath is calculated.

This can also be further enhanced with the ability to apply tool feed adjustment for higher feedrates in areas of the toolpath depending of the tool contact with the stack material, further benefitting the machining process with shorter machine run times. This is done during toolpath calculation whereas normally NC code would need to be optimised after post processing.”

Tebis software includes all functions for optimised and fast roughing toolpaths in a single operation, optimising machines run times and applying higher feed rates where possible and reducing tool wear.

Website: www.tebis.com