Airtech Advanced Materials Group has been extruding and compounding resins for nearly 50 years and has expanded its offering with a line of technologically advanced and reliable resins for use in additive manufacturing.

In a newly developed partnership CEAD –a technology supplier of 3D printing equipment on the frontier of large-scale composite additive manufacturing –has qualified Airtech Dahltram® resins for use on all AM Flexbotplatforms. With exceptional process knowledge, application requirements, and production performance, Dahltram® resins in use on AM Flexbotplatforms offer breakthrough performance and unparalleled flexibility across industries.

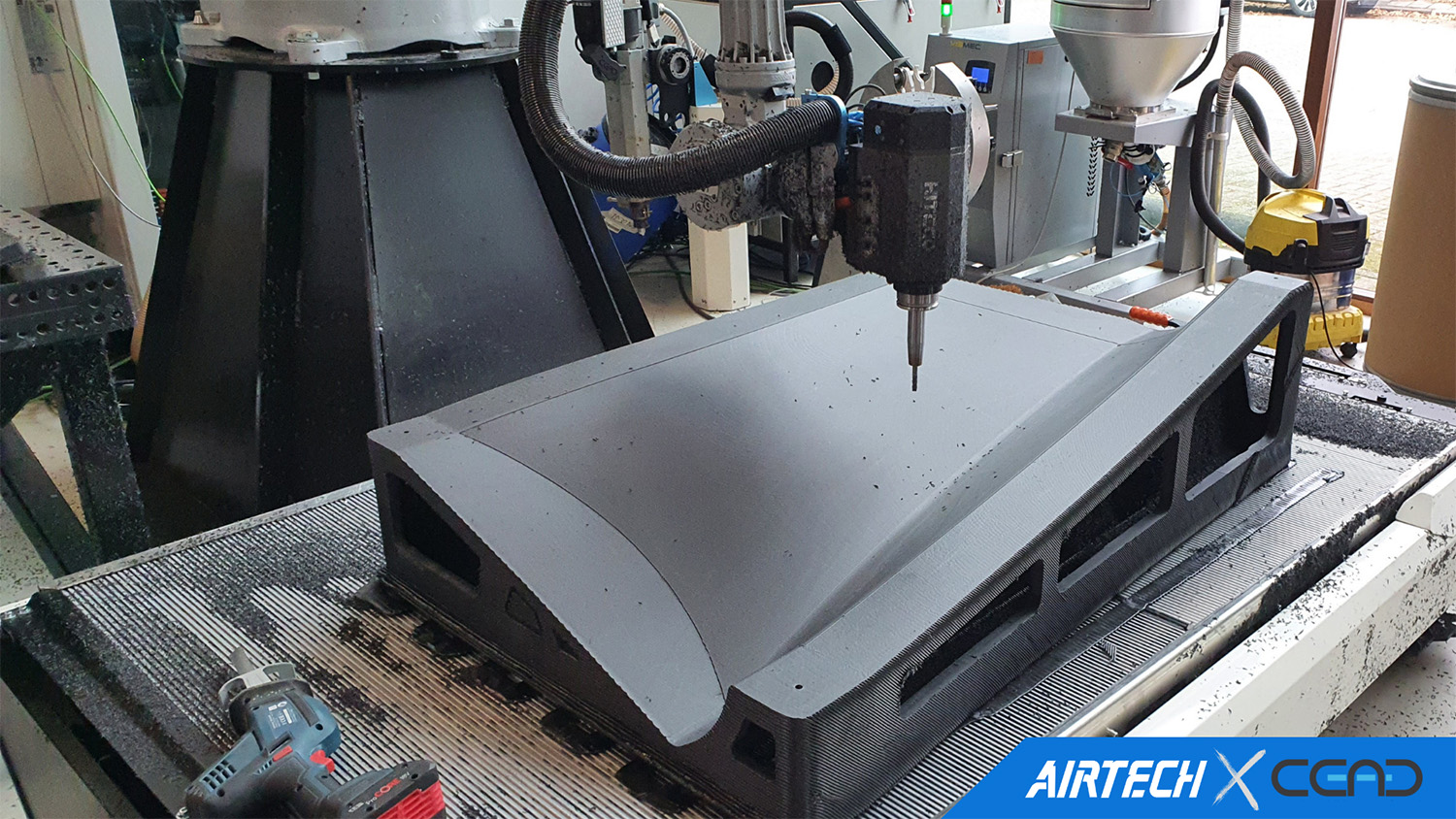

The AM Flexbotis one of CEADs additive manufacturing solution, using Comaurobots directly controlled by Siemens Sinumerik. It offers the unique option to combine 3D printing and milling into one automated process. For moldmaking and tooling applications ideal to achieve the required surface finish. The versatile system provides multiple options which can be integrated to configure the system to customers specific needs.

Airtech Dahltram® resins are suitable for multiple print platforms, offering production flexibility with end-use material validation. Airtech has continued to demonstrate efficacy in composite fabrication with extensive autoclave cycle testing across various platforms with all materials offered. Providing extensive mechanical characterization data, Dahltram® resins are well suited for composite fabrication, as well as metal fabrication and direct to part applications.

This partnership is the latest gain in Airtech’s continued effort to drive innovation, development, and testing in the additive manufacturing market. A product of this collaboration, in the form of a 3D printed composite tool, drew a great deal of attention on display at the Formnexttradeshow in Germany last month.

Website: www.tygavac.co.uk

Website: www.airtech.lu