Composites Evolution will be exhibiting at the Advanced Engineering 2021 show on 3rd – 4th November highlighting its range of prepreg and introducing a new thermoplastic tape manufacturing capability.

Composites Evolution is a developer, manufacturer and supplier of prepregs for the production of lightweight structures from composite materials. A flexible approach allows Composites Evolution to offer short lead times and low minimum order quantities, while decades of combined expertise ensure that in-depth technical support is on-hand when customers need it.

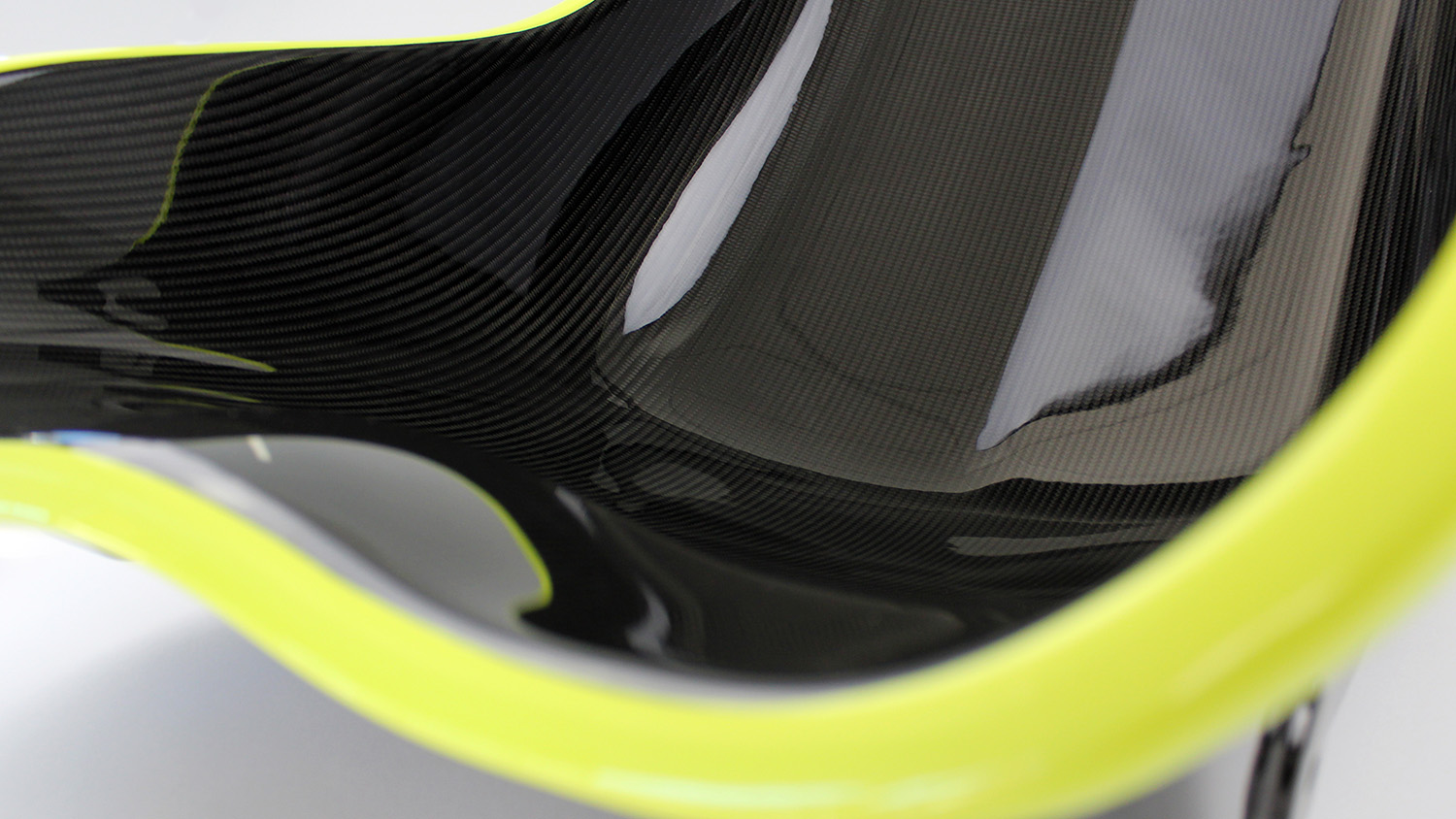

Showcased on stand N90 will be a battery box from a high-performance luxury electric vehicle manufactured from Evopreg® PFC bio-based, fire-resistant prepreg, a rear wing from a Ginetta G56 GTA GT4 race car utilising Evopreg® ampliTex™ natural fibre prepreg, and parts fabricated from the company’s newly-launched Evopreg® PA thermoplastic tape range.

Composites Evolution has a family of specialist prepregs for various applications, including Evopreg® EPC epoxy component prepregs which are a range of pre-impregnated fabrics suitable for moulding into high-performance, lightweight, structural components; Evopreg® EPT epoxy tooling prepregs which have been designed to help composite tooling manufacturers improve the flexibility and efficiency of their tooling manufacturing processes; and Evopreg® PFC fire-retardant prepregs a 100% bio-derived alternative to phenolics for applications where fire performance is a critical requirement.

Evopreg® ampliTex™ combines Composite Evolution’s high-performance Evopreg® epoxy resin systems with Bcomp’s award-winning ampliTex™ flax reinforcements, to deliver a family of materials which offer outstanding performance for component applications.

Composites Evolution will be launching their new range of Evopreg® PA Thermoplastic Tapes at Advanced Engineering; these are manufactured from polyamide-6 (PA6) polymer with unidirectional carbon fibre and are suitable for automated tape laying, winding and compression moulding into high-performance, lightweight components.

Marketing Director Dr Ben Hargreaves will also be presenting a talk, “Sustainable composites for high-performance automotive applications”, on 4th November as part of the Composites Engineering Forum. In this presentation, Composites Evolution will show how Evopreg® ampliTex™ flax-epoxy prepregs can deliver enhanced sustainability for automotive bodywork applications without compromising on performance, and how they can be used to significantly lower the carbon footprint of composite tooling. They’ll also show how Evopreg® PFC fire-retardant, bio-resin prepregs can be used in the production of lightweight battery enclosures.

Visit Composites Evolution at Stand N90 at Advanced Engineering.

Website: www.compositesevolution.com