CompoTech’s PLUS, spol. s r.o (Hall 6, G85) is exhibiting at JEC World 2026, showcasing its high-performance CFRP telescopic mast technology, alongside other components and applications that highlight the advantages of its advanced winding technology. Examples such as carbon fibre (CF) epoxy structural beams and tubes, wound aerostructures with integrated structural components, and a hydrogen storage tank prototype developed for integration into ‘ultralight’ aircraft wings. Existing and development applications for lightweight carbon fibre telescopic mast structures include: wind ships; mobile defence surveillance equipment; radar, navigation and satellite telecommunications systems.

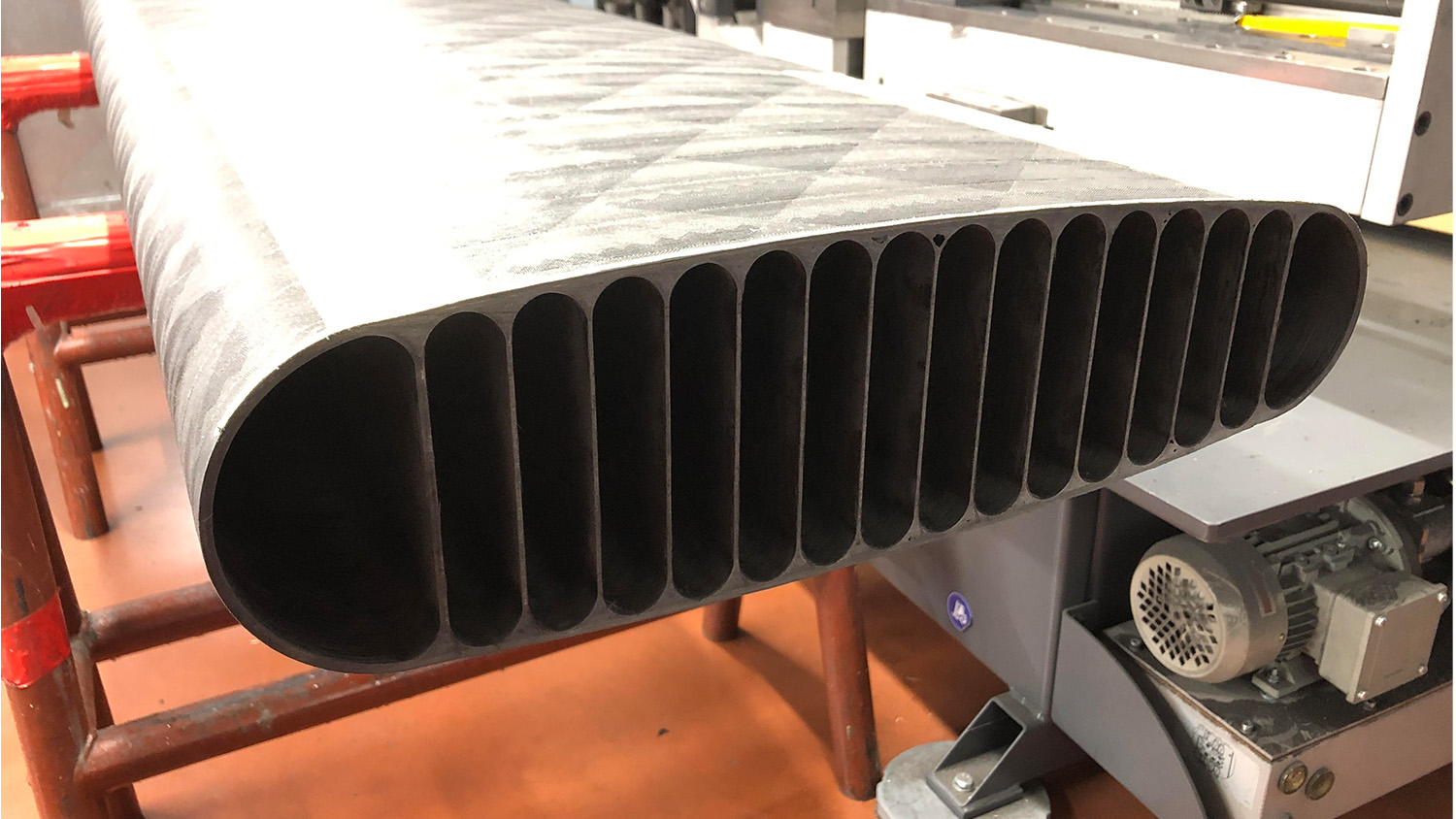

JEC visitors will be able to discover how its proprietary automated winding process technologies can manufacture ultra-stiff, carbon composite components able to replace traditional metals; the outstanding performance is due to the superior mechanical properties achievable using CompoTech’s automated ‘true zero’ axial fibre placement (AFP) and winding production technologies. Unlike conventional winding, which cannot perfectly align fibres, CompoTech’s AFL process allows both pitch and PAN carbon fibres to be placed exactly at 0° along the axis of a tube or hollow beam. The result is an epoxy carbon structural component with exceptional dimensional accuracy, surface quality, and mechanical properties such as: axial stiffness up to 330 GPa, surpassing steel; up to 50% greater bending strength than conventionally wound CFRP beams; components up to 75% lighter than steel, yet performance-matched in stiffness; high dimensional stability.

CompoTech’s versatile advanced winding and filament placement production platform is available as a ‘turnkey’ solution for manufacturers. Each automated machine comes with CompoTech’s advanced winding technologies and proprietary control software as standard, along with after-sales technical and product development support.

CompoTech is an established global supplier of innovative CF epoxy component designs and automated fibre placement solutions. The knowledge and expertise gained from 30 years of successful process development projects and the production of high precision, dynamic automation manufacturing systems has gained the company business in many sectors including: aerospace, agriculture, defence, automotive, transport, bicycles and leisure marine.