Machine builder and composites technology company Cygnet Texkimp [Northwich, UK] has created an open-access Innovation Centre at its headquarters in Cheshire as a development, prototyping and testing space for the advanced materials and composites industry.

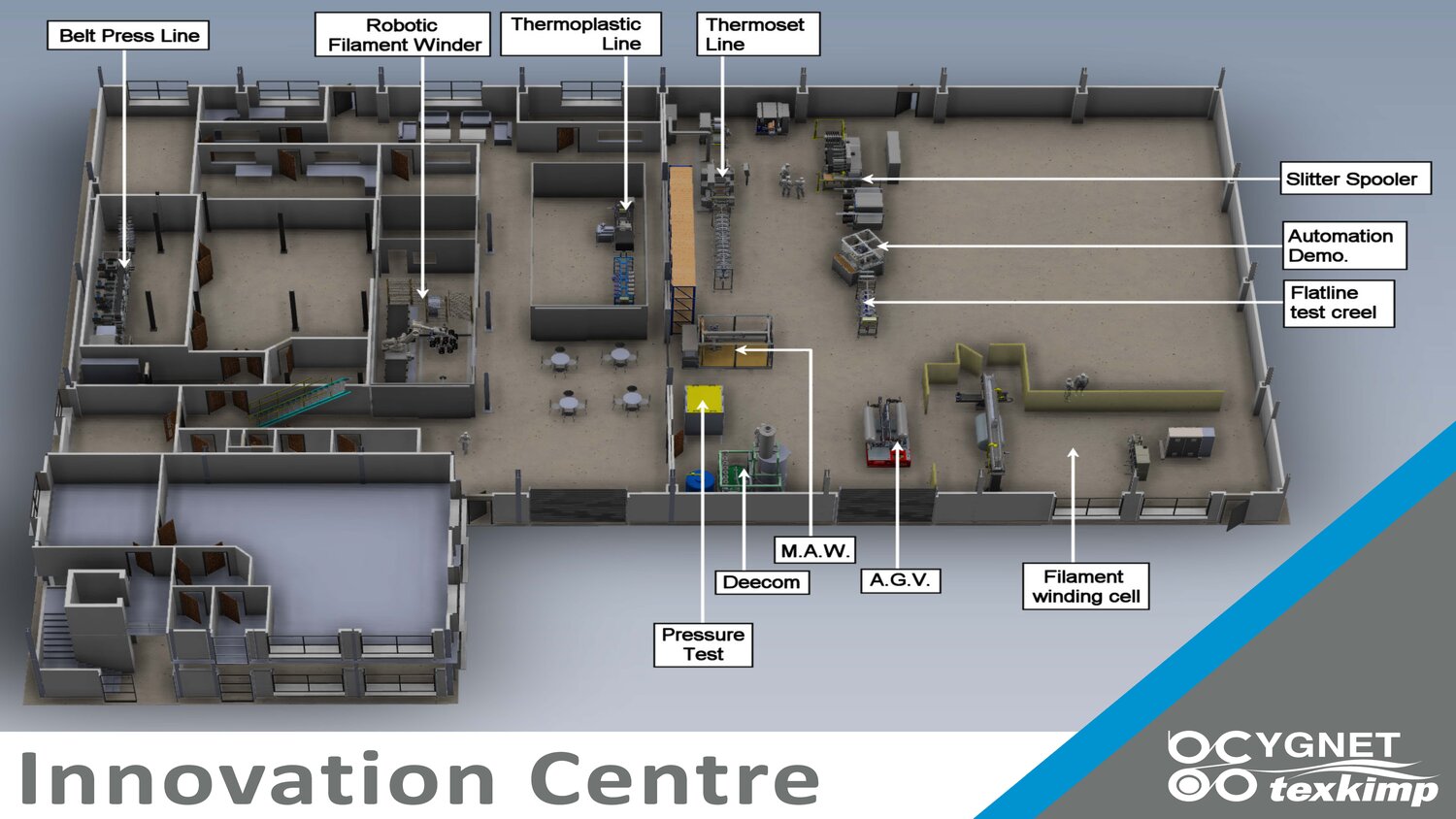

The 15,000 sq ft R&D facility will house machines from across the company’s entire product range including filament winding, prepreg processing, slitting and spooling, automation and recycling equipment.

Its creation marks the latest chapter in Cygnet Texkimp’s work to forward the interests of the industry through the development of equipment used in fibre processing, materials and part manufacturing, and recycling.

Organisations can reserve time in the centre to carry out trials to optimise and validate their process design, evaluate materials, and gather evidence to prove their business case or justify investment.

The facility has been designed to complement existing industry support from academic institutions and the UK’s Catapult Network and is intended to help companies develop technologies from TRL (Technology Readiness Level) 5 or 6 to commercial viability and on to full-scale production.

“Our Innovation Centre forms part of our commitment to reinvest in UK capability and to accelerate learning in this area of materials science, so that organisations involved in the development and application of advanced materials can achieve more and do so more quickly,” explains Cygnet Texkimp CEO Luke Vardy.

“In this way we hope to create an asset for the world’s composites and advanced materials industry, and to support the work of the UK’s composites industry, including the Catapult Network and university-led innovation centres, as a world-class destination for composites technology.”

Andy Whitham, Director of Process Development at Cygnet Texkimp, says: “We’ve created an open-access facility with some of the most advanced fibre processing technologies in the world where our partners can come to push the boundaries of innovation further while developing the next generation of advanced materials and parts in a secure way.

“Our principal aims are to support industrialisation of emerging composites manufacturing technologies, take the guesswork out of process qualifications, and reduce the inherent commercial risk associated with investment in large-scale capital equipment by demonstrating the capabilities of our equipment.”

As a commercial engineering firm, Cygnet Texkimp has a 50-strong engineering team including R&D and product specialists, mechanical, electrical, software and design engineers to support the development work taking place in the company’s Innovation Centre.

“The breadth of expertise within our in-house engineering team means we can leverage other technologies to solve a particular problem and are ideally placed to manufacture specific items or equipment needed to demonstrate a process,” says Andy Whitham.

“Having our own team of specialist software engineers, for example, is a valuable asset and means that operating improvements identified within a trial programme can be made quickly and securely to create the most effective tailored solution for each application.”

The centre will allow Cygnet Texkimp to show the full scope of its diverse and growing range of fibre processing equipment in one place.

“As a machine builder and fibre specialist, we’ve developed a full life cycle of fibre processing technologies from handling and manufacturing to end-of-life management, recycling and repurposing. Being able to demonstrate the full extent of this capability under one roof is a pivotal moment for us and for the industries we serve,” says Luke Vardy.

Technologies housed within Cygnet Texkimp’s Innovation Centre will include:

Direct Melt Thermoplastic Processing Line capable of producing UD, and narrow tape prepregs from standard industrial feedstock.

Multi-Roll Stack, high-speed, short-footprint, vertically stacked prepreg manufacturing line.

High-Precision Slitter-Spooler-Rewinder to process UD prepreg slit tapes.

9-Axis Robotic Filament Winding system with a range of fibre feed and resin dosing systems capable of high tension and thermoplastic winding

Multi Axis and 3D Winders providing high-rate deposition for wound parts of varying geometry.

Automated Filament Winding Cell showcasing Cygnet Texkimp’s work in high-rate manufacturing of composite components.

Composites Reclaiming & Recycling Solutions including those powered by DEECOM®

Spread Tape Line for low crimp fabrics

High-temperature Consolidation Line

Automation demonstration equipment

Automated Guided Vehicle (AGV)

Fibre Unrolling Creels