It has been a busy month for the team at Frewer Engineering.

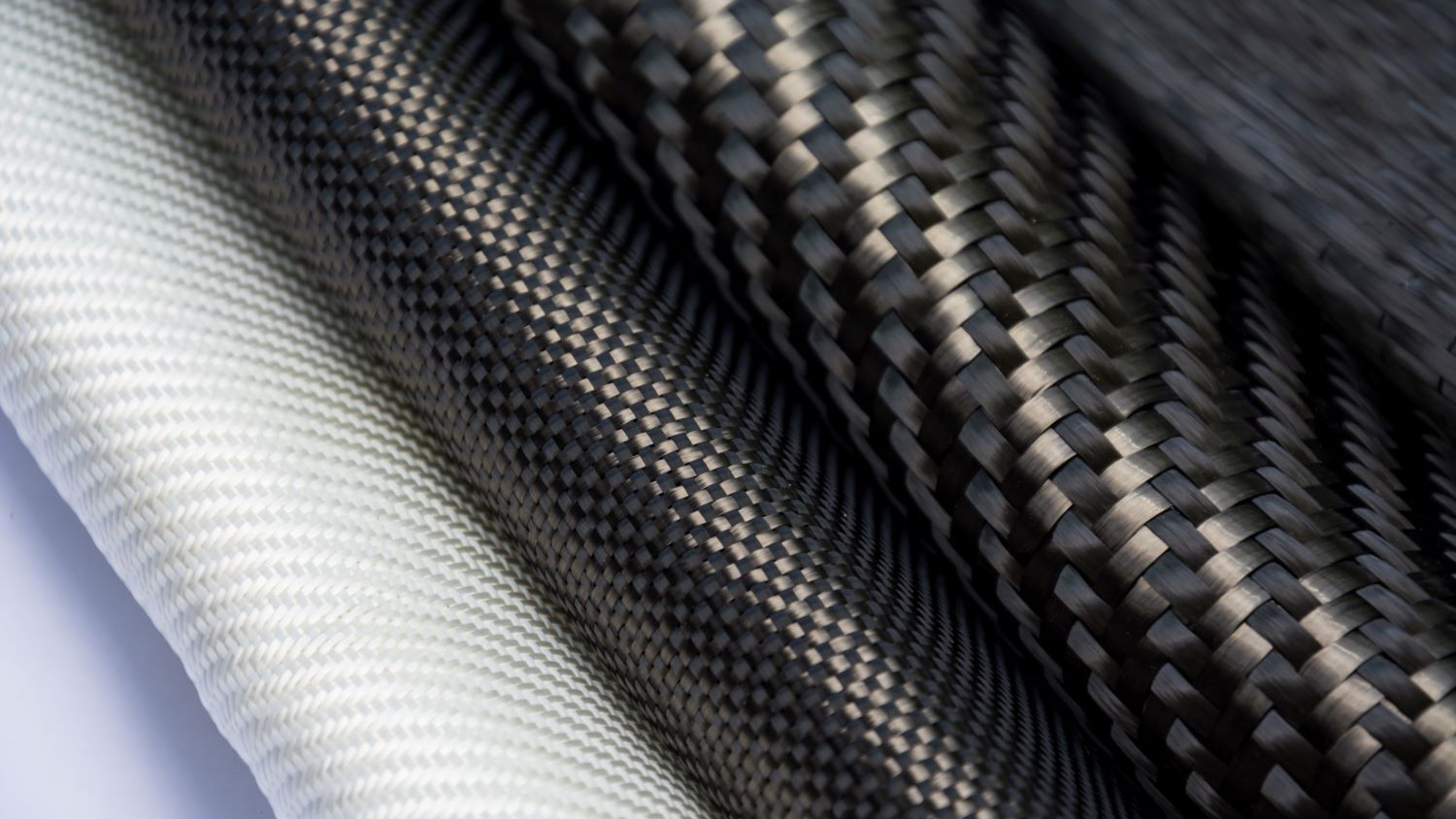

Composite Component Structural Optimisation

Frewer Engineering’s composites specialists are able to integrate both CAD and Finite Element Analysis (FEA) to efficiently optimise structures for desired parameters such as strength, stiffness and weight. In this You Tube video Frewer demonstrates this process on a complex multi-material belt drive system, highlighting the different techniques that can be used to optimise the design. This particular component required significant optimisation to meet the strength and stiffness requirements for accurate belt drive operation, whilst also meeting stringent weight limits for low inertia. In addition, parts of the finished component were used as tooling surfaces for the composite construction.

Repairing Composite Components

At Frewer Engineering, as well as designing composite components from concept level to full manufacturing detail, the company is also involved in the repair of existing composite components. The team are experienced in specifying pre-repair machining and inspections and designing optimal repair layups to be applied to the damaged area, including structural justification. The company also provides detailed repair scheme drawings and support to manufacturing where required. Composite repairs can be required due to a variety of reasons.

More at: https://frewer-engineering.com/project/composites

Composites UK Hydrogen Event Presentation

Frewer Engineering presented at Composites UK’s Hydrogen Showcase Event at the University of Warwick in late May. The company was represented by Simon Apsley and Cameron Abercromby, with a joint presentation, alongside manufacturing partners CCP Gransden of Ballygowan, Northern Ireland. Simon presented on novel high-pressure hydrogen tank shape designs, intended for favourable packaging into vehicle platforms, mirroring the ‘skateboard’ battery pack design that has been adopted for electric vehicles by many automotive manufacturers. The presentation proposed an interchangeable energy source within the vehicle, switching between batteries, or a combined H2 tank, fuel cell and smaller battery combo, within the same flat space envelope, without compromising on the gravimetric efficiency of hydrogen storage.

More at: https://frewer-engineering.com/project/renewables-design-and-analysis