The design of Gas-Turbines and associated testing and ground support equipment is one of Frewer’s specialties. With decades of experience working with leading companies in this area, the company is proud to provide a complete and expert service for its clients. Frewer’s recent work designing the new rapid testing facility for the National Centre for Propulsion and Power at the Whittle Lab showcases its extensive capability in this area. Frewer says its expertise spans, but is not limited to, rotating rigs and rotor-dynamics, high temperature rigs, thermal and structural analysis and ground support structure design.

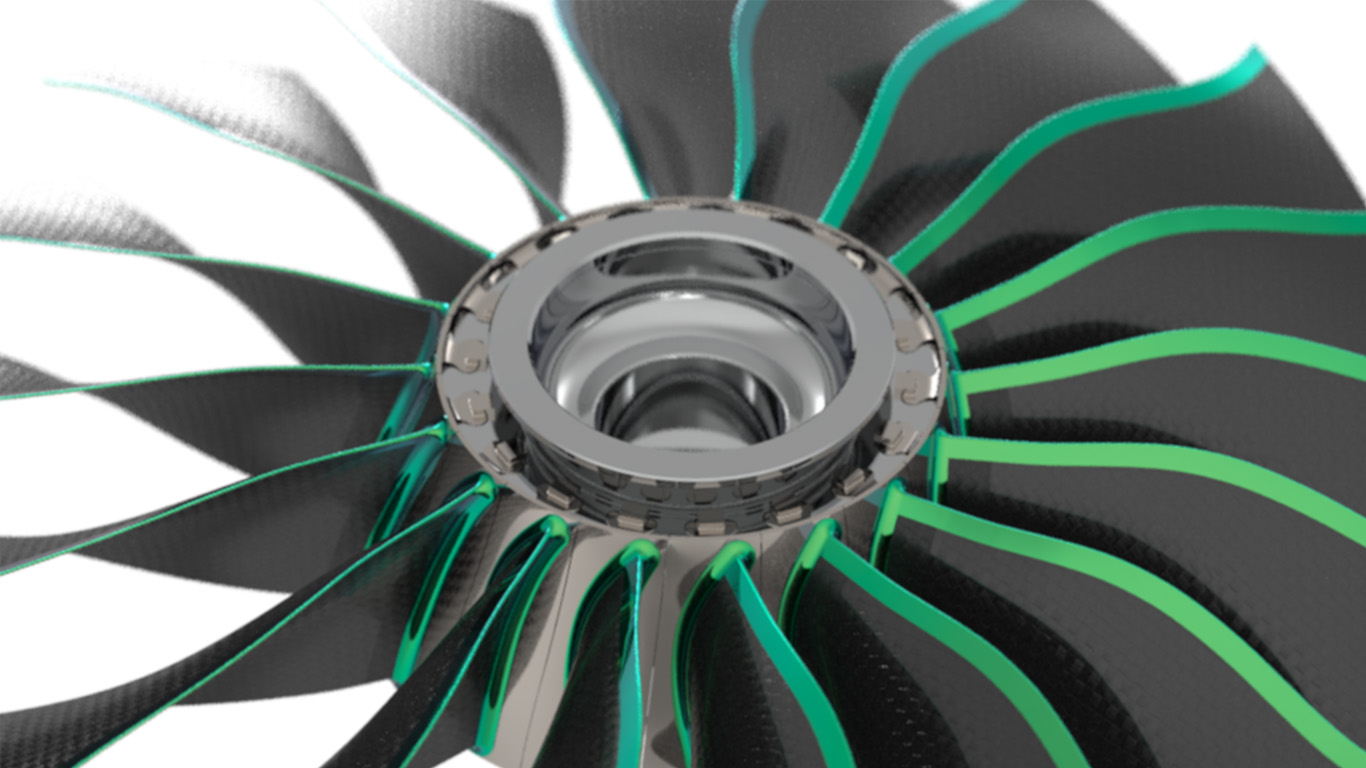

Blades and Rotating Rigs

Relying on the expertise of its engineers, combined with an agile approach, Frewer has experience designing test rigs for: single-arm and fan blade-off testing, foreign body strike, fatigue and many others. Its approach combines its legacy experience with modern commercial and in-house tools to consistently meet customer requirements and minimise turnaround time. Frewer’s engineers have specific expertise in 1D and 2D rotor-dynamic analysis, flow network & secondary air system design, blade strain gauge positioning and explicit containment analysis, providing a complete solution to client needs.

High Temperature Design

High temperature flow modelling, design and analysis is central to what Frewer does. Extreme operating conditions require intricate and robust solutions that drive material choice, system design and risk management strategies. Leveraging advanced technologies, Frewer prides itself on producing intricate and high-fidelity 3D full thermo-mechanical models to simulate transient and steady state operating conditions. The team at Frewer engineering has proven its ability in the delivery of turnkey solutions that meet the industry’s evolving demands, including high-temperature mechanisms, pressure vessels, water-cooling systems and ceramic insulating designs. Specific examples include combustion test rigs and outlet nozzle designs, requiring thermal “un-running” and high temperature mechanism design.

Supporting Structures

Parallel to its thermal and rotor-dynamic capabilities, Frewer Engineering has extensive experience with structural analysis for large ground support equipment and associated ancillary systems. At the cornerstone of its practice is robust structural analysis, including linear, non-linear, vibration and impact analysis. Frewer’s expertise includes design and analysis of pylon systems, high temperature pipework and composite intakes for whole engine testing. The team at Frewer is well versed in design of metallic and composite structures, including full structural assurance to relevant design codes, dynamic tuning, laminate optimisation and adhesive modelling. Frewer’s experience and agility allow it to efficiently iterate between mechanical design, thermal & structural modelling and CFD analysis to provide cost effective, optimised solutions for its clients.

With a rich background of excellence in multidisciplinary design and analysis, including thermal, aerodynamics and structural, Frewer Engineering continues to provide innovative and bespoke solutions for gas turbine equipment design.

Meet Frewer Engineering at ASME Turbo Expo

Frewer Engineering’s Kristian Mahon will be presenting on their new multi-purpose, high-speed, rapid-test rotating rig for the National Centre for Propulsion and Power, alongside the Whittle Laboratory.

The presentation at 9.30am on Wednesday 26th June, will elaborate upon how Frewer has integrated rapid-test technology into a high-speed rig, set to accelerate testing campaigns for single stage fans, compressors & turbines.

Besides taking the stage, the company will also be available at Booth 722.

Website: www.frewer-engineering.com