Glass Reinforced Plastic (GRP) is increasingly being adopted on UK construction sites as contractors look for ways to deliver projects faster, meet compliance requirements, and reduce long-term costs. Traditionally associated with specialist sectors such as rail, utilities, and marine, GRP is now gaining traction in mainstream construction — from large-scale infrastructure to residential housing — due to its durability, ease of installation, and strong safety performance.

Industry applications in pedestrian bridges, industrial facilities, housing developments, and public access infrastructure have highlighted several advantages of GRP over traditional materials such as steel and timber, particularly when assessed over the full life of the asset.

Installation Efficiency and Site Safety

Weighing up to 75% less than steel, GRP can be lifted and positioned by smaller teams without the use of cranes, reducing both manual handling risks and equipment hire costs. Many GRP components are delivered pre-fabricated or cut-to-size, meaning installation can proceed without welding, hot works permits, or on-site surface treatments.

In the refurbishment of Poole’s Wharf pedestrian bridge, GRP Deck 500 panels were carried by hand to the installation point and fixed in place without lane closures or heavy plant, allowing the works to finish ahead of schedule while maintaining public safety.

Addressing the Knowledge Gap

While most site teams are well-versed in working with steel, timber, and concrete, fewer have extensive experience with GRP. This knowledge gap has historically slowed adoption, but targeted training — such as short toolbox talks on safe handling, cutting with standard tools, and mechanical fixing — has helped crews work efficiently with the material. During Network Rail mesh fencing installations, this approach reduced installation times and avoided costly errors.

Fire Safety Compliance

In UK construction, Class 2 fire performance under BS 476 Part 7 is a frequent requirement, particularly for public access and safety-critical areas. GRP can meet this rating using fire-retardant resin systems and manufacturing techniques that limit flame spread without affecting other performance characteristics such as corrosion resistance and slip resistance.

Performance in Harsh Environments

In coastal, chemical, or high-moisture settings, steel’s vulnerability to corrosion drives ongoing maintenance costs. GRP is inherently resistant to rust, rot, and chemical attack, making it particularly effective in marine, wastewater, and industrial sites.

At Copenhagen Kastrup Airport, GRP structural profiles were selected for a blast wall in a saline coastal environment, replacing steel to eliminate future corrosion treatment costs while meeting strict aviation safety standards.

GRP in Residential and Low-Rise Construction

While often associated with industrial or infrastructure projects, GRP is finding new applications in residential housing and low-rise developments. Developers and architects are using GRP for balconies, terraces, and access ramps where slip resistance, fire performance, and low maintenance are critical.

GRP balconies and staircases can meet Class 2 fire performance requirements while avoiding the repainting or replacement cycles common with timber or coated steel. On roofs, GRP walkways offer safe maintenance access without adding excessive weight or compromising waterproofing. Cladding and façade applications benefit from GRP’s weather resistance and long-lasting visual appeal, reducing upkeep for building owners.

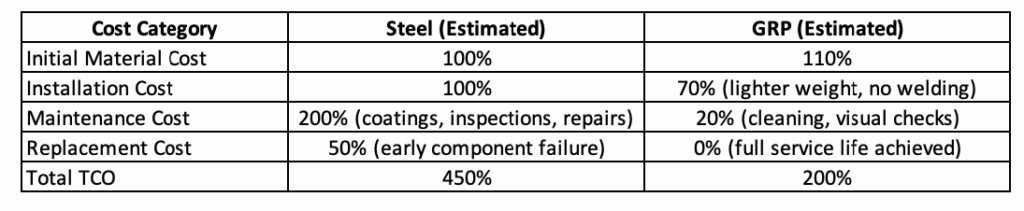

Total Cost of Ownership (TCO) — The Financial Case

When considering material options, many decisions focus on initial purchase price. However, whole-life costing shows a different picture.

TCO Formula:

TCO = Initial Material Cost + Installation Cost + Maintenance Cost + Replacement Cost over Asset Life

Comparing steel and GRP over a 50-year design life in a coastal or industrial environment:

While GRP may have a slightly higher initial material cost, savings in installation, maintenance, and replacement can cut total lifecycle costs by more than half. This is particularly significant for projects where downtime is costly or operational continuity is critical.

Quality Assurance and Long-Term Assurances

GRP products manufactured to BS EN 13706 for pultruded profiles and BS EN 4592 for industrial flooring are supported by robust QA processes, dimensional checks, and mechanical testing. Many suppliers offer warranties ranging from 10 to 25 years, with an expected service life of 50+ years when correctly installed.

In projects such as Alyth Substation, these assurances allowed the client to meet safety standards while reducing long-term operational risk in a high-voltage environment.

Conclusion

GRP’s growing role in UK construction reflects a shift toward materials that deliver more than just structural performance. Installation speed, reduced maintenance, compliance with safety standards, suitability for residential and industrial projects, and lower total lifecycle costs are combining to make GRP a viable alternative to steel and timber in a wide range of applications.

For contractors, developers, and architects, considering GRP at the specification stage can lead to safer sites, faster builds, and better financial outcomes over the life of the asset. Further technical details, standards compliance data, and case studies are available from Engineered Composites, the UK’s largest independent GRP supplier.