In collaboration with SHD, JCB Aero have developed a floorboard panel system for the MRO market that offers a substantial weight reduction. Utilising FRVC411, an innovative, toughened and flame-retardant epoxy resin system created by SHD, the durability of the new floor panels was significantly increased while weight and costs were reduced.

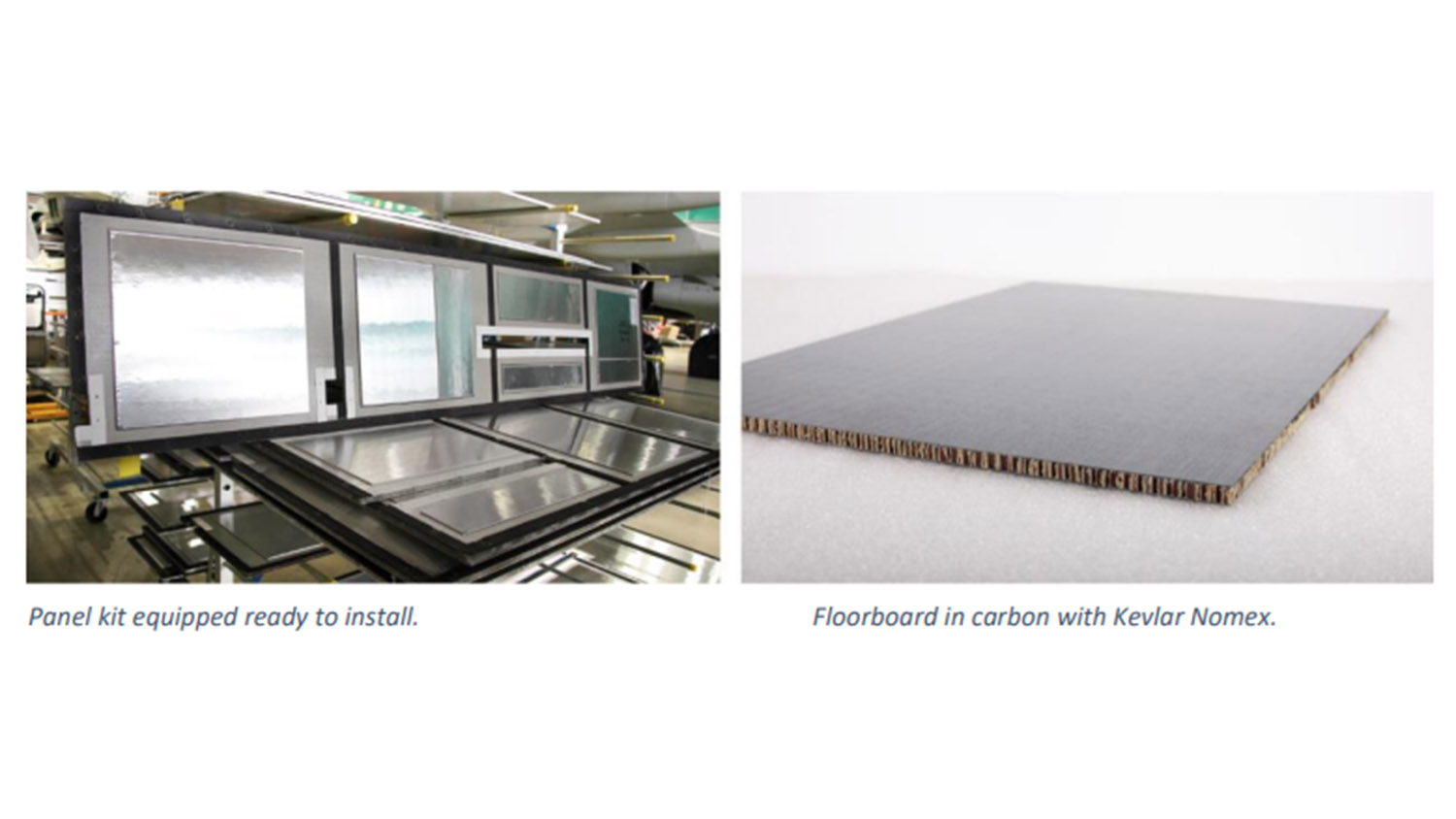

JCB Aero has developed a floorboard panel system, compliant to BMS4-17/20/23, for the MRO market. These panels offer a substantial weight reduction and through their EASA-certified design (Part 21J), production (Part 21G) and EASA Part 145 capabilities, the JCB panels can be installed on 95% of Boeing Cabins on variants including B737, B747 and B777.

Tested for full conformance with aircraft interiors standards, FRVC411 is a toughened, flame retardant epoxy resin system designed to cure between 65°C and 140°C allowing flexibility in component manufacture for aircraft and rail interior applications. Utilising the lightweight, high strength unidirectional carbon fibre prepreg increased the durability of the new floor panels and supported both a reduction in weight of the part and the cost of manufacture.

JCB Aero, partnering with SHD, boasts significantly faster production times compared to traditional

OEM floorboard manufacturing. Prepreg materials can be delivered in just 3 weeks, allowing JCB Aero to create custom floorboards with multiple Supplemental Type Certificates (STCs) in a much shorter timeframe.

Eric Cagnat, Chief Operating Officer at JCB Aero, praises their successful collaboration: “The team at SHD were easy to work with and provided a tailored solution at an attractive price. As the FRVC411 is a versatile resin system, it helped to reduce processing times whilst maintaining our high-quality requirements. Overall, we were very impressed with the product and will return for future projects.”