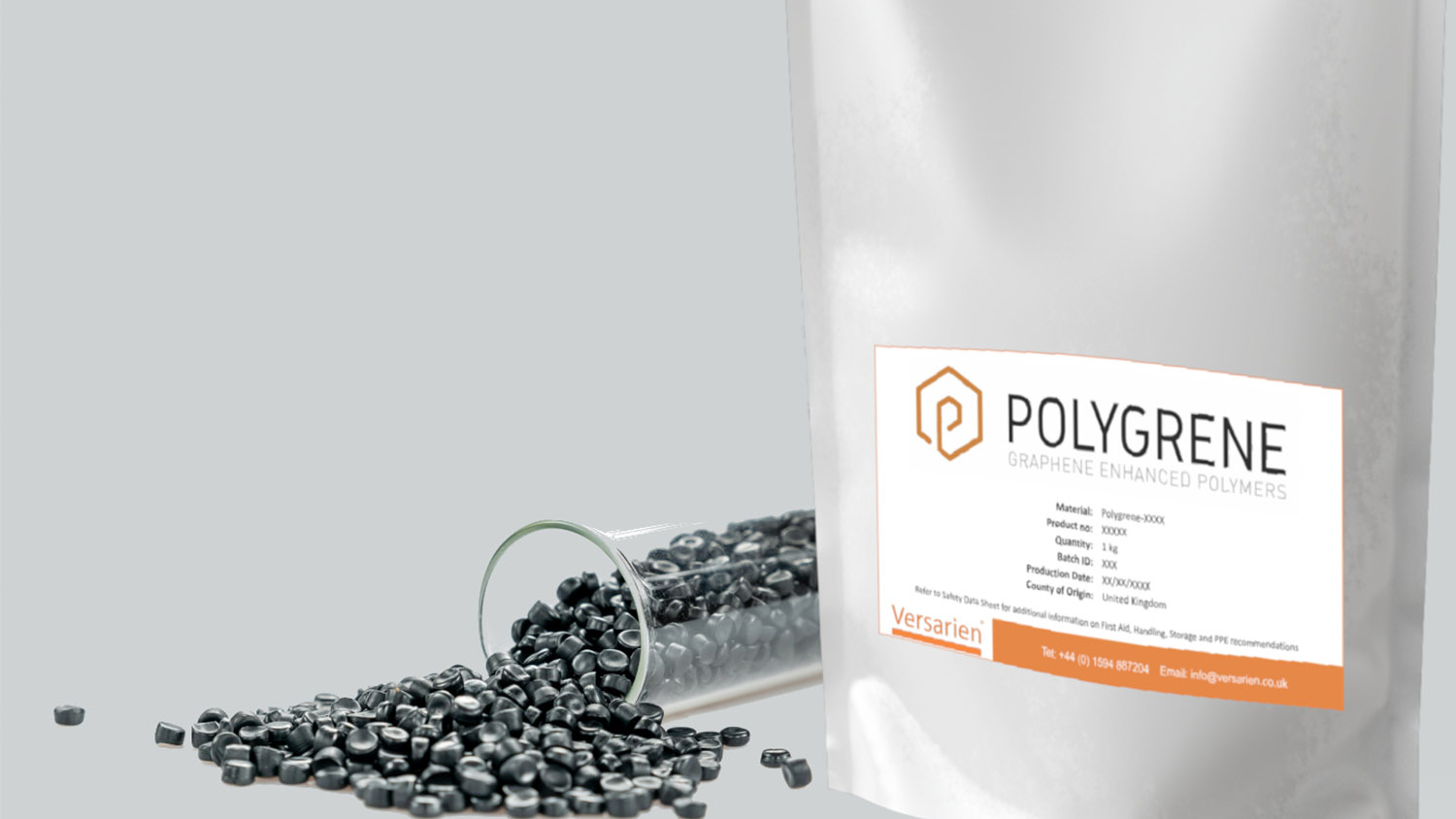

Versarien plc (AIM: VRS), the advanced materials engineering group, is pleased to announce the launch of a new comprehensive portfolio of graphene and related nanomaterial based thermoplastic polymer compounds and masterbatches under Versarien’s PolygreneTM umbrella. This culminates from several years of work in collaboration with world-leading experts at the International Institute for Nanocomposites Manufacturing (IINM) based at WMG, at the University of Warwick. The new PolygreneTM compounds are expected to have potential commercial applications in areas as diverse as sports equipment, construction products, aerospace and automotive components.

Since 2018, Versarien subsidiary 2-DTech Ltd (2DT), CompositesUK member, has funded PhD and postdoctoral researchers to understand the use of its Nanene™ graphene powders and other nanomaterials in thermoplastic systems. Dr David Reinoso-Arenas, the first 2DT funded PhD student, with support from the EPSRC Doctoral Training Programme, worked with Versarien’s Nanene™ materials in thermoplastic elastomer (TPE) systems and joined Versarien full-time last year as part of the team at Versarien’s subsidiary Cambridge Graphene Ltd.

Commenting, Dr David Reinoso-Arenas, said: “The new PolygreneTM thermoplastics portfolio is a culmination of my PhD research, some of which is due to be published in peer-reviewed journals. Since then we’ve been able to further develop and test these materials using different nanomaterial fillers and process conditions to fully optimise the resulting product performance. My PhD experience at the IINM and WMG was really enjoyable and enabled me to work closely with industry to ensure that the outputs of my research could be validated and have commercial viability.”

David’s PhD was performed under the supervision of Professor Tony McNally, whose team has an established capability in incorporating a wide range of nanomaterials into bulk polymer systems.

Commenting, Professor Tony McNally, who leads the Nanocomposites Research Group at WMG, University of Warwick, said: “Working with Versarien over the last few years has given the IINM and WMG access to alternative graphene materials that have shown interesting phenomena when blended in these TPE systems. By tuning the nanofiller loading and optimising process conditions, David’s research showed that exceptional gains can be achieved in mechanical properties across the board (tensile strength, modulus, elongation at break, toughness and abrasion resistance) without compromising any properties. The addition of graphene also highlights improvements in polymer processing which may offer lower energy usage and, therefore, improving sustainability.”

Versarien continue to work with Professor McNally through a funded PhD position in 2D material based rubber systems, making use of the IINM’s new state of the art rubber processing and testing capabilities With support from the High Value Manufacturing Catapult (HVMC), WMG has established a world class facility for the study of elastomers.

Dr Stephen Hodge, Versarien’s CEO, added: “We look forward to continuing our collaboration with the IINM and WMG in rubber processing and understanding the interactions of our graphene and other 2D materials in these more complex systems, and hope to be able to demonstrate significant benefits that can impact upon real-world applications.”