International plastic net manufacturer EXPO-NET® Danmark A/S is exhibiting at JEC World 2023, Paris (Hall 5, Q56), which runs from 25 – 27 April. The range of 100% recyclable, extruded thermoplastic resin flow mesh products produced are extensively used in composite manufacturing as essential vacuum infusion processing aids. The company’s head office, manufacturing, engineering, R&D and main warehousing facilities are located in Hjørring, Denmark; the 12.000 sq. m site is ISO 9001:2015 and 14001:2015 certified.

EXPO-NET’s global composites customer base includes major producers in the wind energy, automotive, aerospace, marine and construction industries. EXPO-NET resin flow meshes are specified to ensure reliable and consistent high quality moulding of large, complex, fibre reinforced plastic (FRP) and sandwich design composite parts; up to four different custom made resin flow mesh grades can be used in specific areas of an infused part to increase productivity and to avoid premature resin hardening and air voids.

New Technical Developments for JEC World 2023

The EXPO-NET management team remains committed to being innovative, finding ways to keeping adding value to its customers, and being as sustainable a business as possible. Two of EXPO-NET’s latest technical developments that reflect this commitment are being showcased during JEC World 2023.

New vacuum infusion resin flow mesh comparative data

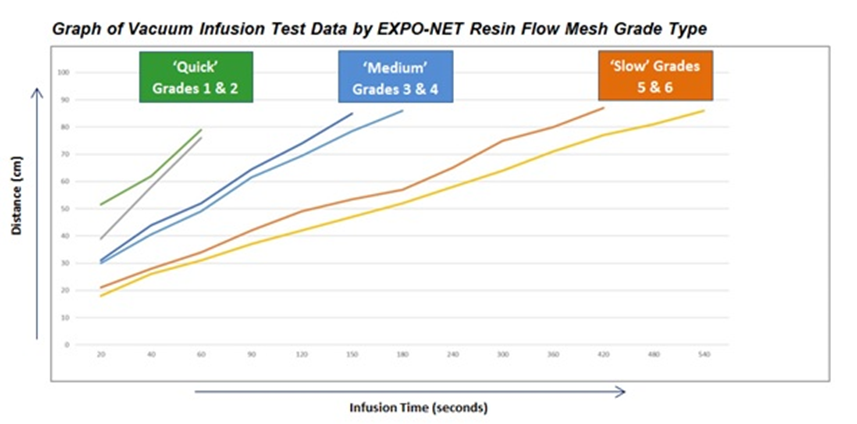

Visitor to the EXPO-NET stand in Paris at JEC World this year will be able to see and discuss the new ‘Vacuum Infusion Resin Flow Mesh Technical Processing Guide’. The guide provides comparative data on the different types of EXPO-NET flow mesh grades available – Quick, Medium or Slow.

The new processing guide has been developed to better understand the rheological impact of specific flow mesh grade types to match the specific resin grade, laminate design and shape of the FRP part being infused. The data helps customers select the right combination of mesh products in different areas of a mould to optimize vacuum infusion resin flow control, improve process predictability and ensure part quality

Having tested the six most commonly specified resins flow mesh grades by OEM wind energy and marine customers, a test programme is ongoing to obtain flow test data for the rest of the EXPO-NET resin flow mesh range, which should be completed and made available in the near future.

New Bio-attributed plastic flow mesh products

EXPO-NET’s R&D team is investigating possible bio-attributed thermoplastic polymer formulations that can be extruded to provide netting and flow mesh products with properties which match the specifications of currently used PE and PP polymer raw materials. The renewable ‘mass balance’ resource feedstocks being evaluated can be produced from tall oil extracted from kraft pulped Nordic softwoods. The aim is to develop a new range of sustainable products of equivalent performance that are not only 100% recyclable, but also have a significantly lower carbon footprint.

During JEC World 2023, the EXPO-NET business development team is hoping to meet with companies interested in discussing a possible collaboration to develop bio-attributed resin flow mesh products for their specific market and application needs.

EXPO-NET is highly responsive to changing customer requirements, rapidly altering custom made flow mesh products as needed, as well as holding key safety stocks for strategic customers.