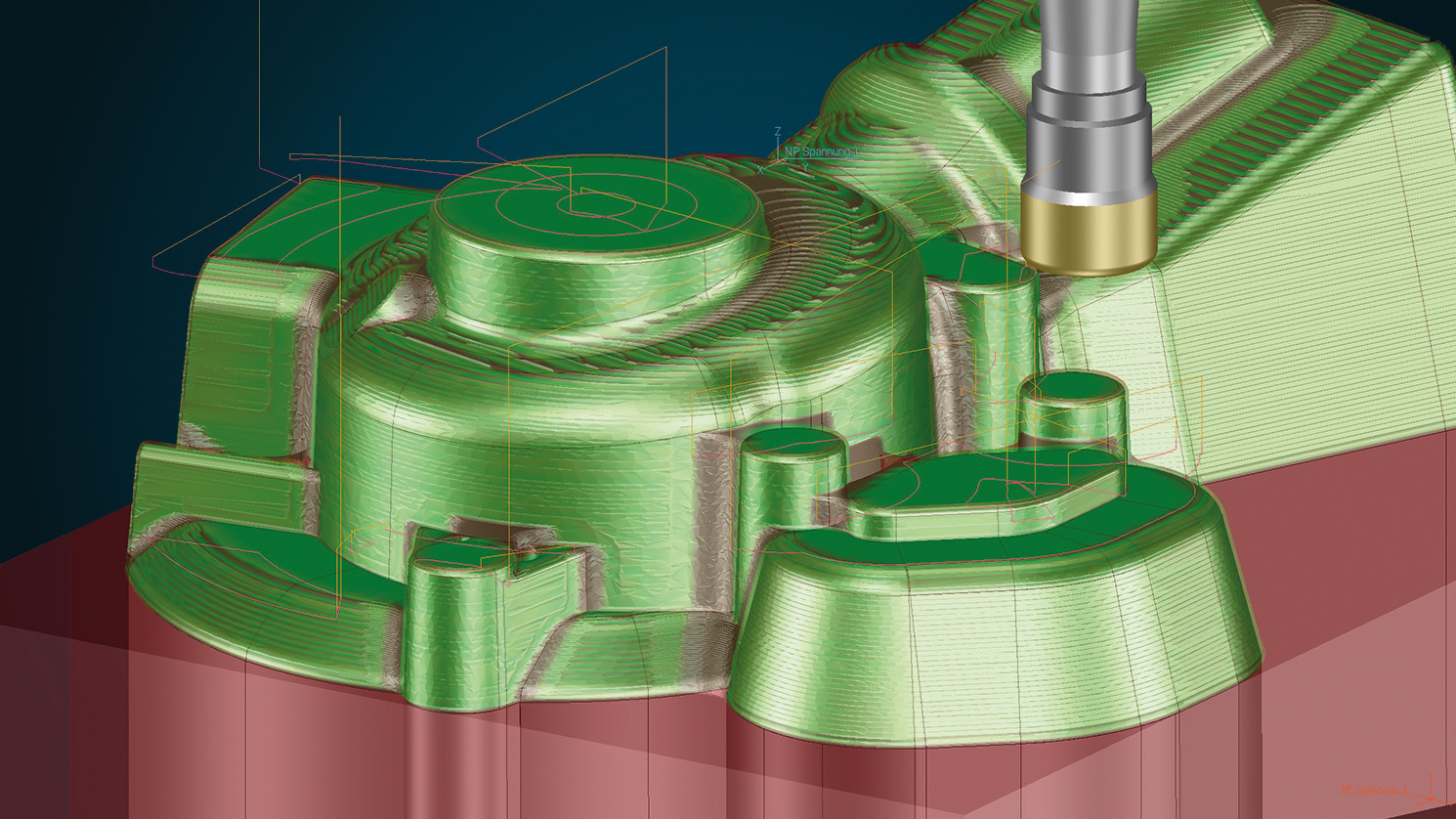

The third release of Tebis’ 4.1 comes with even more new developments: shorter programming times with improved NCJob technology, complete collision control accounting for material removal, automatic detection of planar areas – these are just a few of the most important highlights that benefits the users in their daily work and that allow them to quickly and easily reach your goals.

As a robust hybrid CAD system with logical and intuitive user guidance, Tebis 4.1 lays the foundation for manufacturing processes that can be automated and that prepare you for the future.

CAM – Automation

Shorter programming time thanks to improve NCJob technology.

Your CAM programs are finished more quickly with these new features:

The new release automatically applies interactively defined milling areas from previous NCJobs. CAM programming is also significantly simplified – you can easily manage combined machining operations in an end-to-end CAM template.

CAM – Milling

Optimal cutting conditions for roughing rotationally symmetrical parts.

The turning/milling operations: In addition to cylindrical parts, tapered parts such as screw conveyors can now also be machined with high efficiency. The tool first roughs the part to the maximum possible depth with a low stepover and large downfeed in a single pass. Then, it machines the residual stock from bottom to top with a smaller cutting depth – precisely to the stock allowance. This procedure reduces tool wear and ensures a high material removal rate on the machine. The user can easily program the final finishing operation with a special function: Only the strategy is replaced – the system does the rest.

CAM – Lathe

Turning with convenient cutting off of the part.

Parts can be cut off from bar stock with a special function for automated machining on lathes or turning-milling centers. It be can quickly and easily define the optimal cutting conditions for feed rate and speed on material exit.

CAD – Active surface design

Precise results when trimming deep-drawing and bending parts.

The “Create development curves” function can be used to quickly and easily determine theoretically designed trim edges for flanges on deep-drawing and bending parts. The material thickness of the component and the location of the neutral fiber are accounted for – and the result is highly precise, with no manual reworking necessary. The quality of the resulting curves corresponds to that of the original curves.

CAD – Parametric design

Conveniently control changes with user parameters.

Every imported data set needs to be prepared for CAM programming in design. This usually takes many individual work steps: Bores for clamping systems must be placed, tilt axis systems defined, fill surfaces designed, blanks created, connection points for setups generated, clamping devices positioned and retract planes defined. These many individual steps can be highly automated in Tebis using parametric CAD templates. These templates can be extended as needed and can be adapted to meet customer-specific requirements. Users can still be highly flexible: Changes like selecting a different clamping system can now be controlled directly and conveniently with the user parameters in the object tree.

CAM – Drilling

Flexibly use special cutters.

When using combined special cutters with several cutting edge areas of different diameters, only the diameter of the active cutting edge determines whether the tool is suitable for the specific machining task. This enables highly flexible use of special cutters for drill-milling and thread milling in bores and circular pockets – regardless of the diameter of the largest cutting area. The plausibility check also only accounts for the properties of the cutting area actually used.

Website: www.tebis.com