Hydrogen storage is of growing significance within the aviation industry, with many viewing it as a potential solution in the challenge to reduce carbon impact. Currently, aviation emissions are responsible for 3.5% of climate warming caused by humans, indicating an urgent need to develop more sustainable alternatives.

The appeal of Hydrogen is that, when generated from renewable sources, it would emit zero carbon dioxide emissions, whilst still maintaining current flight routes. This interest is evident in Airbus’s commitment to developing the world’s first fully hydrogen-powered aircraft by 2035.

Hydrogen does however pose several challenges in terms of fuel storage, as it delivers less energy by volume than kerosene fuel, meaning huge quantities would be required to power an aircraft.

Polar Technology Management Group, an engineering business specialising in both metallic and composite technology, has a wealth of experience in the design, development and manufacture of technologies to support the “hydrogen economy”. Leveraging expertise in lightweight, composite high-pressure cylinders and hydraulic accumulators, and in the area of cryogenic liquified gas storage down to liquid helium temperatures, Polar Technology have developed solutions for gaseous and liquid H2 storage.

These solutions have been focused on three main areas: extremely light weight cylinders offering industry-leading gravimetric efficiency, the novel ‘Hydrogen in a Box Solution’ where volumetric efficiency and space constraints of high-pressure cylinders are important, as well as technologies for the cryogenic storage of liquified H2.

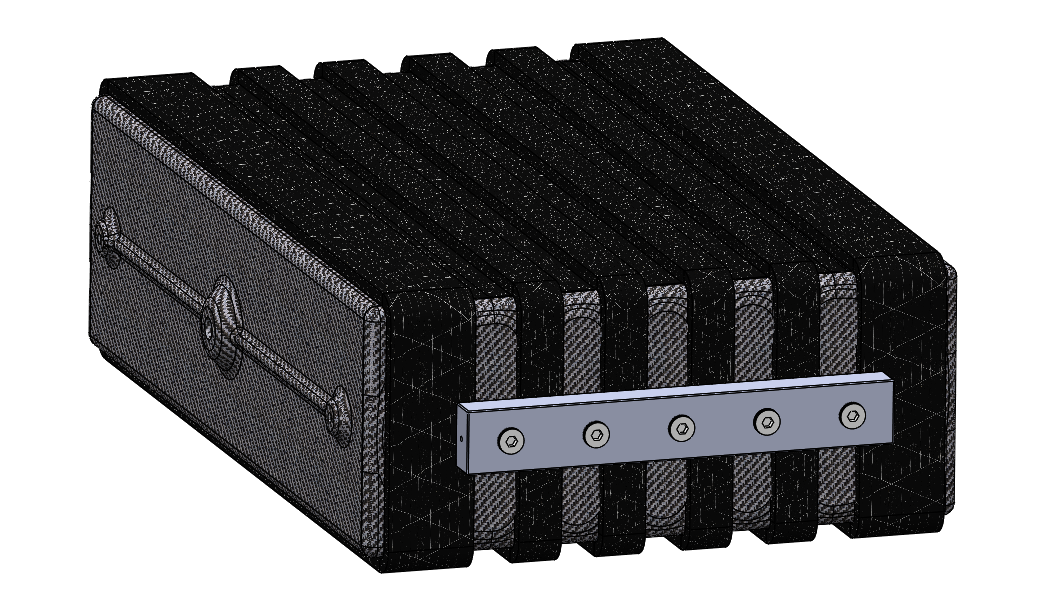

The “Hydrogen in a Box” Solution

At this year’s Farnborough International Air Show, Polar Technology debuted the ‘Hydrogen in a Box’ solution, which offers greater volumetric efficiency than other industry equivalents, allowing for a more distributed storage solution, making it perfect for the demands of aerospace.

There is a great deal of flexibility around the geometry of these parts, opening up new opportunities to efficiently store hydrogen in places where cylinders would not be appropriate, such as in the wings of an aircraft or under the floor and possibly even as part of the structure itself.

The technology is compatible with a variety of different liner materials, from metallic to composite components. It has also been extensively pressure tested, with existing prototypes being evaluated for both 350Bar and 700Bar applications, with options for liquid H2 storage under evaluation.

Polar Technology’s solution minimises the amount of empty or lost space within the vessel, as well as enabling the capacity to easily increase volume when required. Furthermore, “Hydrogen in a Box” has the capacity to integrate valves and control systems within the design, removing the need for extra manifolds at system level, whilst it doesn’t require the use of a chassis to hold separate vessels together, unlike many similar products on the market.

Kieran Burley, the Lead Engineer on the project, said “This is a very exciting time to be working on hydrogen storage solutions; there are so many opportunities for innovation, optimization and integration. Combining novel design solutions with innovative manufacturing processes means we can package hydrogen storage efficiently in a series of co-dependent chambers to form a storage bank, rather than fitting a number of standard independent cylinders into the space.”

Daniel Chilcott, Group Business Development Director, said “Enabling technologies for a sustainable and heathier future is rooted in our vision and ethos as an organisation. Looking at the huge opportunity that exists for technological advance in Hydrogen, together with the impact on carbon reduction potential. I am certain Polar Technology’s solutions such as ‘Hydrogen in a Box’ can provide our customers significant overall system improvements.”

Website: www.polartechnology.co.uk