Additive manufacturing is emerging as a game-changing technology in the aerospace and related industries. Here, Garry Sellick, additive manufacturing manager at Airframe Designs, looks at the pace of change and the opportunities it presents.

As the aviation industry tries to keep pace with rapidly emerging technologies, it should grasp the opportunities they present.

At Airframe Designs, we look beyond the technology itself. We believe in research and development, collaboration with industry partners and academia, and the ongoing investment in the skills of our people to add tangible benefits for our customers and the supply chain.

Indeed, additive manufacturing can be adapted for diverse industries including automotive, space, nuclear and rail with advantages that have not been possible before.

This technology directly addresses some of the pain points of the industry as it grapples with long supply chains, demanding schedules and challenging lead times whilst also considering the environmental targets of Net Zero.

We are working with our customers in partnership to achieve a number of key benefits:

• Reducing lead times from concept to product delivery

• Improving precision and quality of all parts

• Minimising waste and energy consumption

• Reducing overall lifecycle costs

The efficiency of additive manufacturing combined with the environmental benefits it offers are making it an increasingly compelling choice of technology for many of our customers.

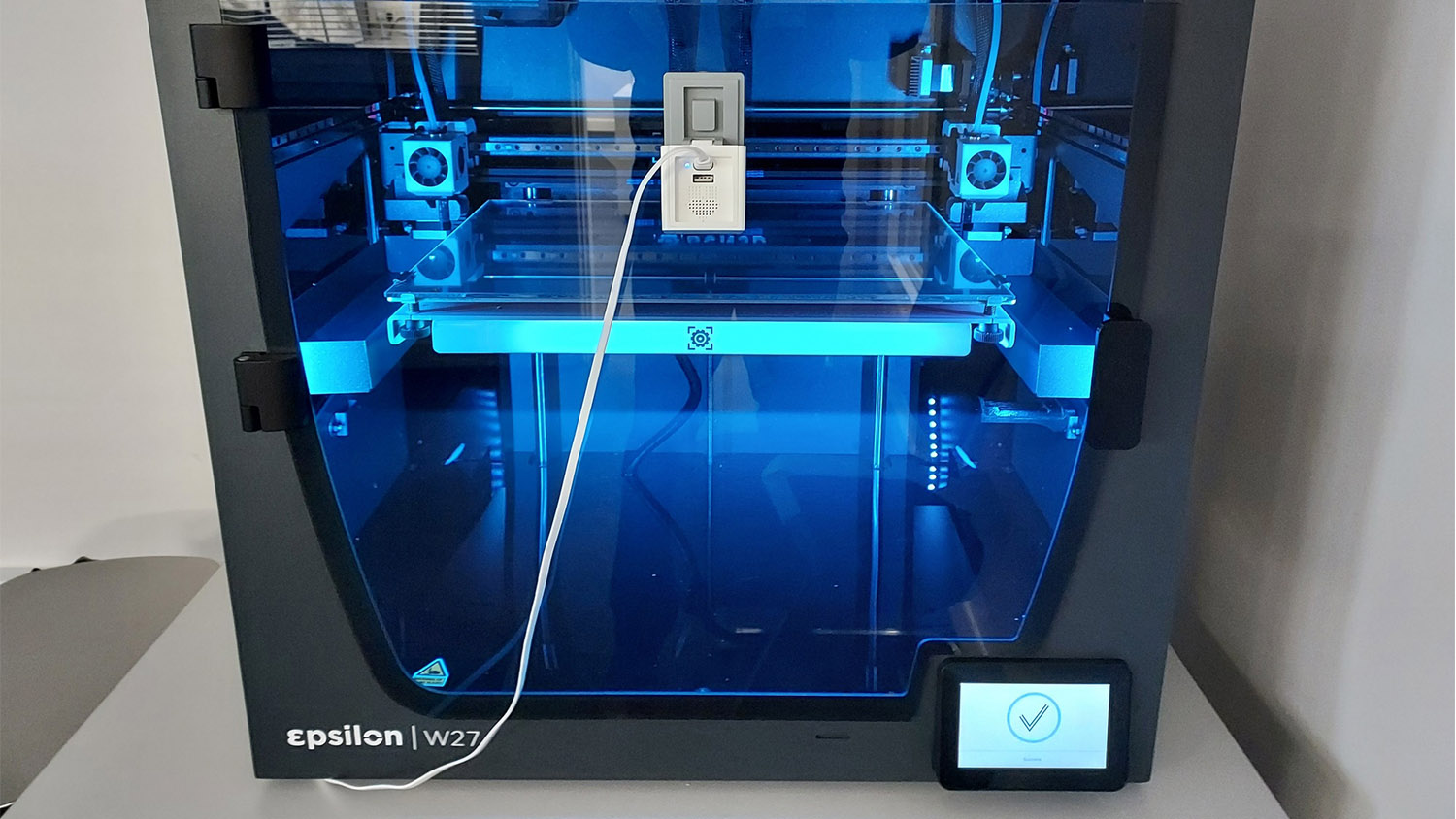

Recently, we have invested in a second 3D printing machine – a state-of-the-art Stratasys Fortus 450mc – as well as a new five-axis milling machine and sophisticated resin printing technology.

This investment is now working for us and our customers with all the commercial and environmental advantages we would expect as we progress new ways of working.

As an example of our innovative approach, we are aiming to be a world-first in aircraft part production through a 3D printing project with the National Aerospace Technology Exploitation Programme (NATEP), an 18-month government-funded programme using water-soluble support in the 3D printing process with faster manufacture and less potential for damage than current manual support removal methods.

Behind the scenes, the skills of our senior engineers, combined with the young talent we are nurturing, make it all possible. Their commitment to learning and innovation means we are continually improving in everything we do for ourselves and our customers. This adds up to engineering excellence. This is the Airframe Way.

We are always looking for people with the right experience and the relevant skills, and we invite them to apply if they want to join our team.