Tebis is a market-leader for CAD/CAM/MES technology with vast experience serving customers in many industries including model, pattern, die and mould making as well as component manufacturing.

One of Tebis unique offerings is Tebis specialist 5-axis mill trimming and laser cutting package for improved machining operation safety, quality, and efficiency as well as ease of uses. Tebis trimming package has been widely used for moulded plastic parts, composite components and other material parts.

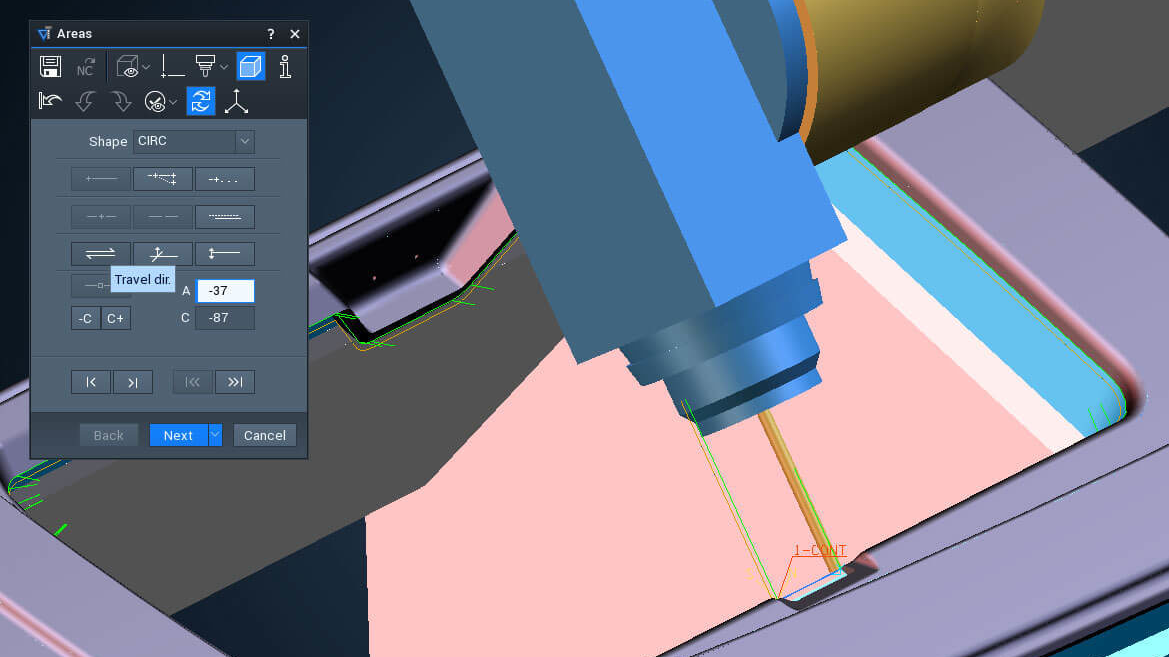

Optimise Toolpath Vectors and Tilt Directions for machine safety

Having a variety of tools that can accurately and concisely adjust tool directions means that Tebis has full control of the machine head, even during the programming process by way of Tebis virtual machine technology. This is particularly important with a typical asymmetric head configuration on a trimming machine, where a lack of control of which side of the asymmetric head is being used can lead to catastrophic collisions.

Toolpath correction

Tebis can correct and modify an existing toolpath easily with just the addition of the modified geometry: Tebis has the facility to import an extra piece of geometry such as a curve, and add this into the toolpath. So we don’t need to modify any other CAD data or even reprogram the operation, just open the toolpath operation and add the extra geometry and Tebis will take care of the rest for you.

Automation in trimming

Using programming templates, Tebis is able to give absolutely consistent tool paths and cutting conditions by predefining the parameters. This ensures that all output NC programs are using the same stepovers, lead ins/outs and safety clearance.

Full collision avoidance

Safety is critical in all areas of machining, especially for 5-axis machining. Tebis collision avoidance is working in the background at all stages of the programming process. Tebis checks the spindle and machine head, tool holder and cutting tool against the finished component and fixtures. It is also capable to control all machine movements, including movements and links between toolpaths. Therefore, the software is able to have total control over all potential collisions thus, safeguarding the part, tooling and machine tool.

Reverse postprocessing, importing historical programs

Tebis can import old teach and learn programs or even old CAM generated programs. – This allows you to adapt historical programs from an old machine to a new machine and even modify and optimise old teach and learn programs for modified components.

Specialist fixture design for trimming operations, saving fixture design CAD work time

Trimming operations are usually for small batch parts and fixtures need to be designed to hold the parts. Tebis offers specialist trimming fixture CAD design tools to efficiently design trimming fixtures with ease, saving a lot of fixture design CAD work time.

Website: www.tebis.com