Leading composite material kit manufacturer, Velocity Composites, has joined an elite group of aerospace companies that have successfully completed the National Aerospace and Defence Contractors’ Accreditation Programme special process audits to the highest level.

The company came through the rigorous NADCAP kitting service provider special process audits for its Burnley and Fareham facilities with 100 per cent pass rate across both sites.

This elevates Velocity Composites UK sites to the highest merit programme level under NADCAP, with the next audit in 2025.

Jon Bridges, CEO of Velocity Composites, said: “This is a proud moment for the business. As we grow our offering globally, our customers can be assured that they are benefiting from the highest process quality when they outsource their materials management and kit manufacture to us.

“Our quality standards and processes are what we live by and we continually seek to lead the industry in the very highest technology-driven standards in close collaboration with our customers and partners as we widen our capabilities.”

NADCAP is an industry-managed approach to conformity assessment of ‘special processes’ that brings together technical experts from prime contractors, suppliers and representatives from government to work together and establish requirements for approval.

Arturs Musperts, Quality Assurance & Compliance Manager (UK) for Velocity Composites, said: “We have achieved this working together in a closely knit team. Our future goal is to maintain the standard we have set before us to help us grow wherever our customers are located.”

Velocity Composites has now had six NADCAP special process audits, since joining the programme in 2017, without any non-conformities.

Velocity Composites manufactures advanced carbon fibre and ancillary material kits for use in the aerospace and associated industries from its sites in Burnley and Fareham in the UK and in Alabama, US, where it opened a manufacturing facility last year.

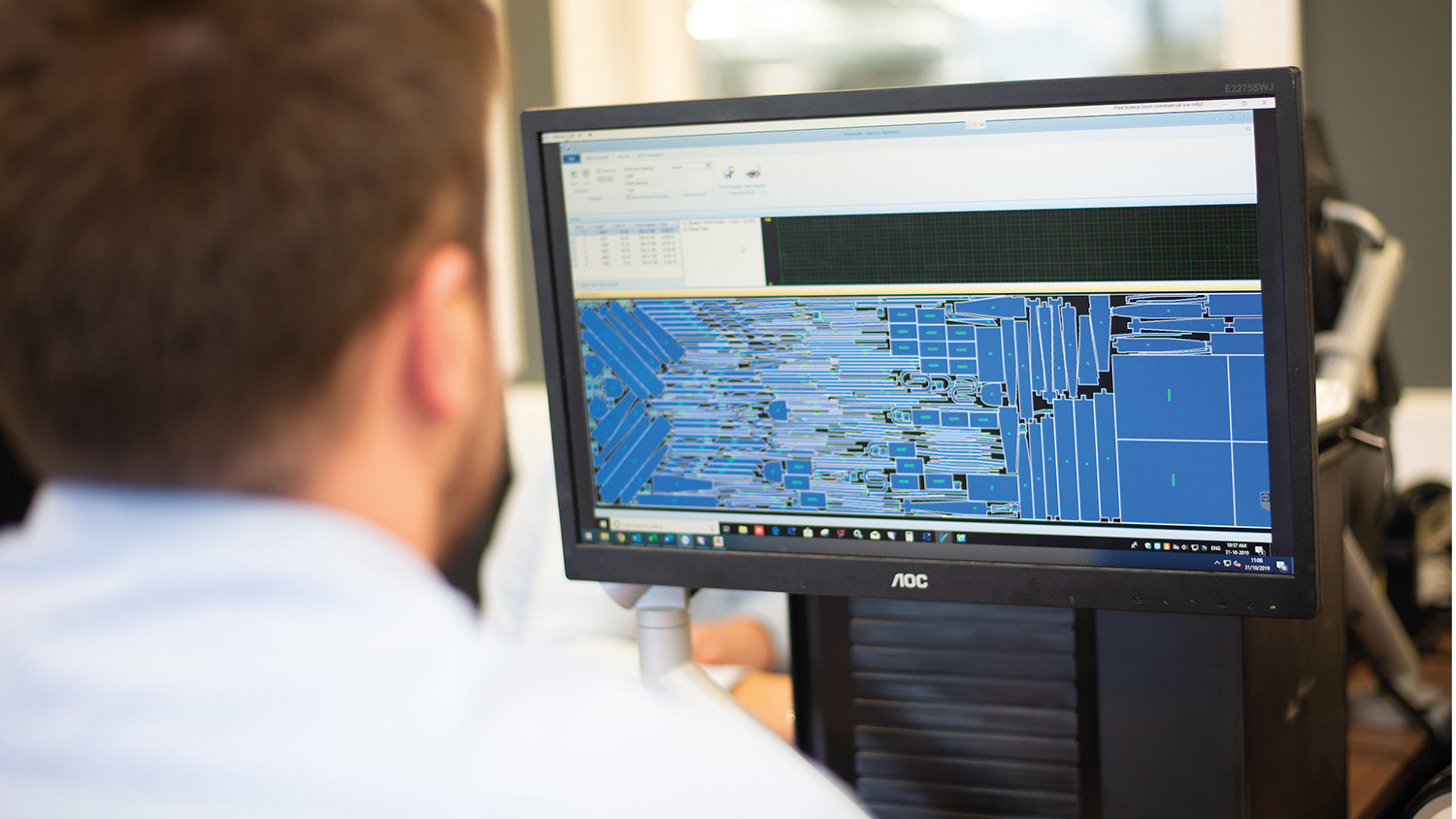

The company uses its process knowledge, business processes and proprietary software and technology to manage the material supply chain, reduce the amount of material required by its customers and reduce the associated material waste when making aircraft parts, both material and process time.