James Cropper, the Advanced Materials specialist, will be launching EMITEC™, its new, tuneable conductive nonwoven solution at JEC World 2025. EMITEC seamlessly integrates lightweight EMI shielding and electrical conductivity into composite structures while offering unmatched flexibility and ease of handling.

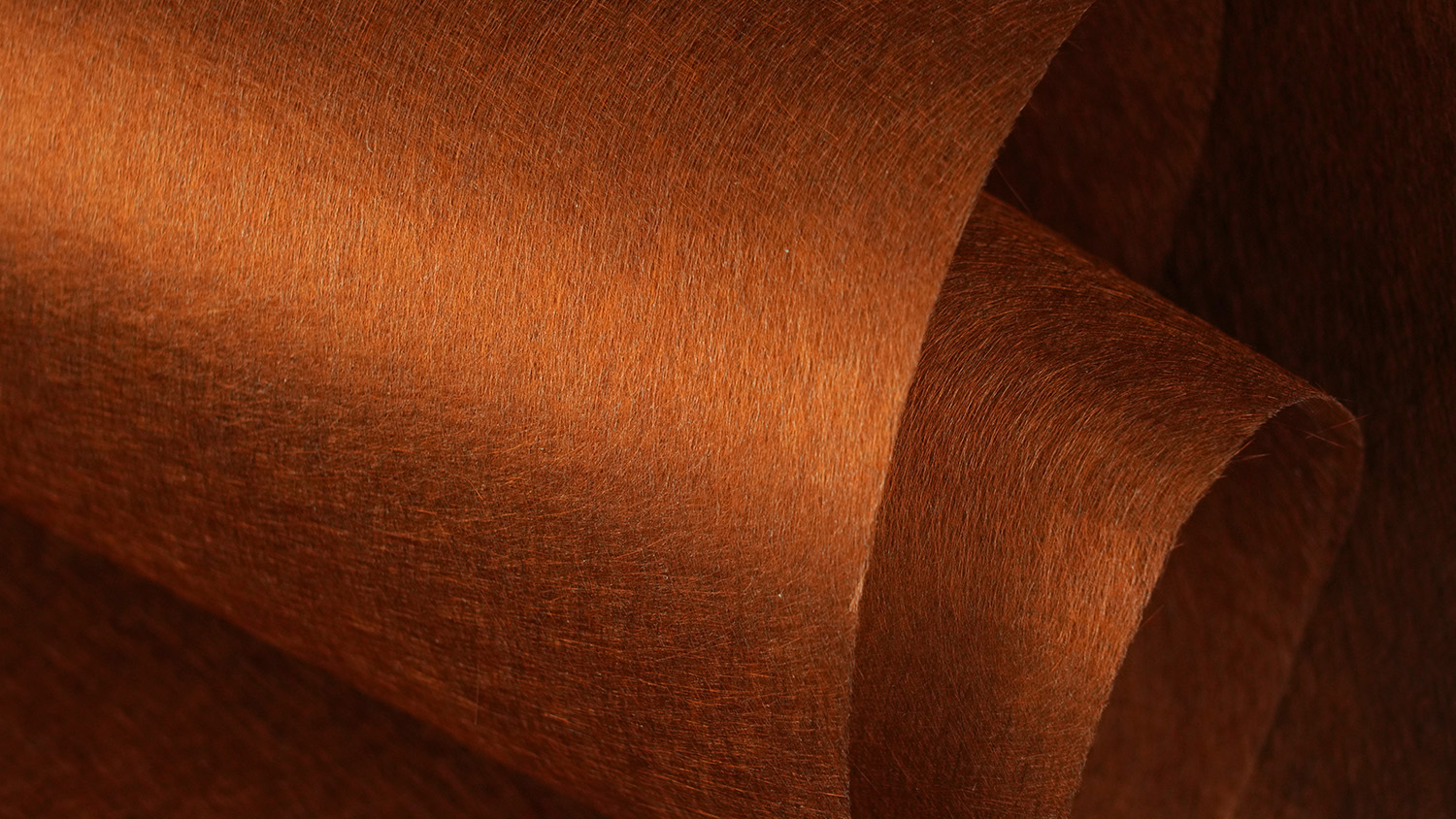

Available in areal weights from just 4g/m2, EMITEC materials are up to 19 times lighter than traditional mesh and foil products and engineered to deliver precise shielding performance based on application needs. The range of weights available, combined with material options including nickel coated carbon, copper coated carbon, and silver-coated nylon veils, means that manufacturers can fine-tune conductivity and EMI protection without overengineering, ensuring optimal performance without unnecessary weight or material costs. This makes EMITEC an ideal shielding solution for lightweight-critical industries such as aerospace, electric vehicles, and high-performance electronics.

As well as being heavier weight, traditional EMI shielding methods often require additional process steps, thus increasing manufacturing complexity, material waste, and weight. EMITEC solves these challenges by being incorporated directly into the composite structure during production. Compatible with all common resins and manufacturing techniques, the veils deliver EMI shielding that is integral to the part as well as enabling more efficient production and enhanced durability.

More rigid shielding materials like traditional meshes can also be difficult to shape and integrate into complex composite designs. EMITEC offers superior flexibility, making it easy to conform to curved and intricate surfaces without compromising structural integrity. This ensures reduced flex fatigue, better mechanical performance, and smoother integration into advanced composite structures.

Dr. Mandy Clement, Technology Manager at James Cropper Advanced Materials comments that: “Creating functional, lightweight materials has been a critical objective for us. The market is flooded with EMI solutions and products that are over-specified and overweight, and we wanted to change that. EMITEC offers high shielding performance, over a wide frequency range (30MHz up to and beyond 40GHz) at a comparatively light weight, making it the ideal choice for EV battery enclosures, eVTOL aircraft, and next-generation electronic devices.”

As well as launching EMITEC at JEC World, the event is the first public showing for James Cropper Advanced Materials since rebranding from Technical Fibre Products. EMITEC will be on display alongside James Cropper’s well-established OPTIVEIL® range, which includes ultra-lightweight glass, polyester, and thermoplastic nonwovens optimised for use as carriers or supports for adhesive films and fragile materials.

These veils are engineered for compatibility, enabling rapid, even resin or adhesive wet out, resulting in a thin, consistent bond line and improving the resilience and handling of the final product. Key benefits include faster processing times, improved quality, and reduced waste.

Find out more about EMITEC, or visit booth N40, hall 5 at JEC World 2025.